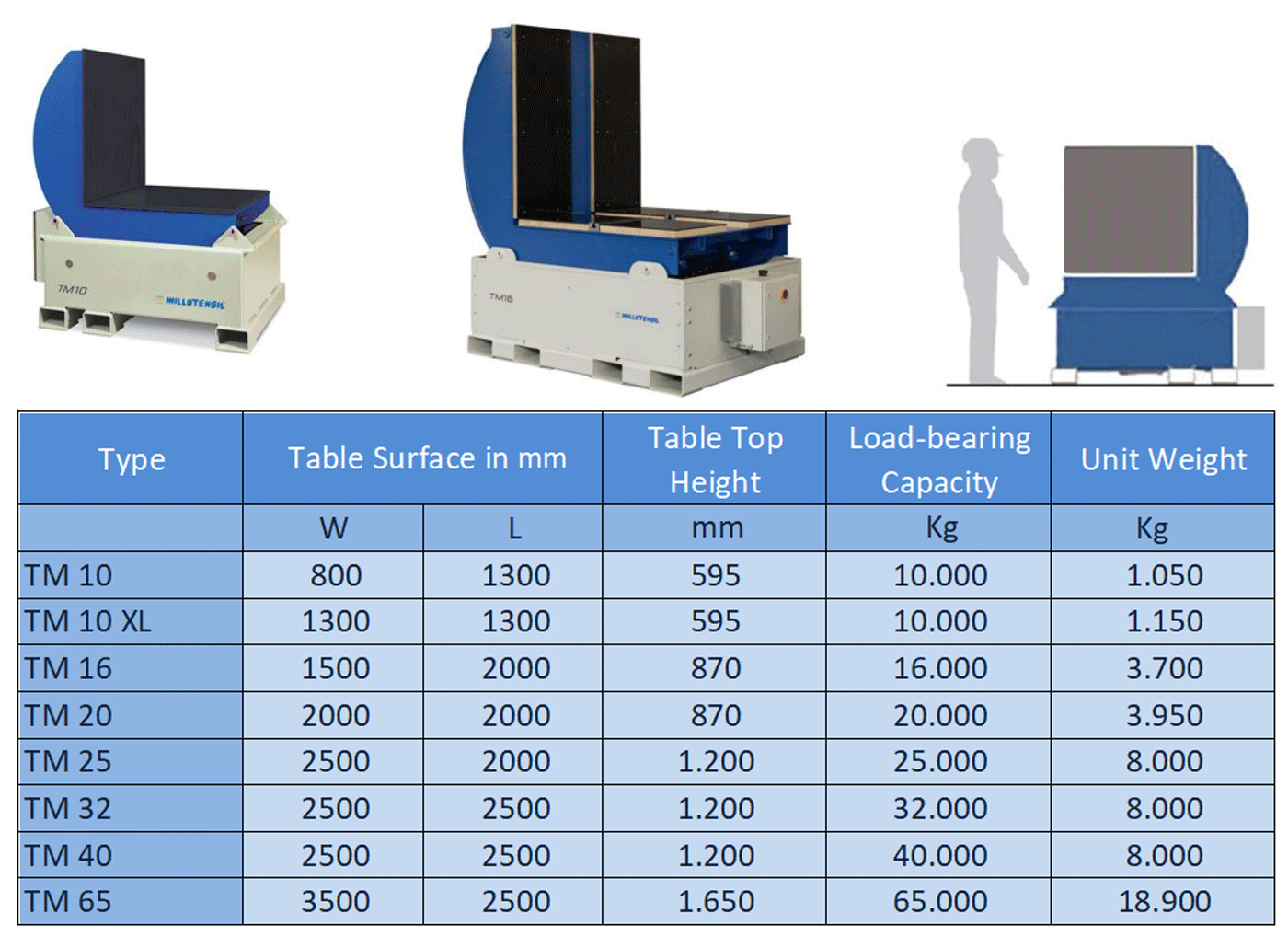

HANDLES HEAVY MOULDS SAFELY AND EASILY

TOOL MOVER

The Tool Mover enables the gentle and safe turning of sensitive injection moulds and heavy tools. It is versatile and can be easily relocated since it is not anchored to the floor and is very compact in size, can be moved with a hoist (lifting points) or lift truck (fork insertion points).

The Tool Mover’s table has a low supporting surface, allowing the open tool to be cleaned while on the table itself.

The Tool Mover can be equipped with PU plates to protect the tool and includes a siren to indicate when the table is in operation.

Operation of valuable, sensitive and heavy tools (up to 65 tons):

- injection moulding

- Automotive

- Tool making

- Die-cast aluminium

- Stamping / bending technology

- containers

- electrical appliances

- and much more

The Tool mover was created to solve the following problems

- Problems with conventional rotating and turning equipment:

- Potential damage to expensive tools

- Damage to hoist brakes and ropes

The benefits of Tool mover

- The load is turned over at its centre of gravity to ensure a smooth transition

- The table has a frequency-controlled drive for soft starting/stopping

- Minimizes the risk of damage to expensive moulds or tools

- No risk for the operator

Optional attachments and safety equipment

Tool Mover guard bracket

Bracket construction as distance protection for the operator

- Bracket construction for the front danger area

- Bracket construction for the rear danger area

VWBG-V Load ring, UNC thread. rotating 360°, pivoting 230° ball bearing

Total control

- Safe to operate outside the danger zones

- Two hand operating device

- Wireless operating device

- Table top polyethylene

- Optional: anti-slip support Made of steel mesh / polyurethane.

Request Tool Mover Catalogue

Simply complete the form below and we'll send you our latest catalogue.

Let's focus on Blue Line Product Categories

Spotting presses for assembly, adjustment, checking and repair of small dies

Spotting presses for assembly, adjustment, checking and repair of medium and large dies

Die splitters for assembly, adjustment, checking and repair of dies for cutting, die casting, etc.

For the safe handling / rotation heavy injection moulds, tools

and other objects