SPOTTING PRESSES FOR ASSEMBLY, ADJUSTMENT, CHECK AND REPAIR FOR MEDIUM AND LARGE MOULDS

MIL SERIES

The press is used for splitting, adjusting, maintenance and try-out operations on dies and moulds (thermoplastics, die casting, thermosetting, rubber and blanking).

It is also possible to inject special waxes at low pressure into the mould.

The MIL series consists of 2 lines: Classic and Compact Series, declined in different models depending on the size and capacity of the platens.

Available platens sizes are from a minimum of 1.200×1.000 mm (47×39 inches) to a maximum of 5.000×2.500mm (196×98 inches).

Each line is available in two variants: the floor version and the pit version.

MIL CLASSIC SERIES

The die & mould spotting presses of the traditional MIL/CLASSIC series feature the extensible plate exit on the side, towards the short side of the distance between columns. They are typically used in the plastics, rubber and die casting sectors.

This solution allows tilting on the extensible plate short side up to 70° on both sides. In this version, the upper plate, too, is tilted on the short side from 100° to 180°.

The MIL/CLASSIC series provides great advantages compared to other solutions with long side rotation

- Better working ergonomics, granting the operator to have easy access to any mould part without the use of platforms;

- Much shorter total press height above ground, which often reduces excess costs for foundations;

- Wide base press structure with greater stability;

- The two mould-halves are located on the same side, so operators have an overview of the whole mould and can work more comfortably

MIL COMPACT SERIES

The MIL/COMPACT series die & mould spotting presses are a riveting innovation to optimize adjustments in the die casting sector.

They feature the extensible plate exit on the backside, towards the longest side of the gap between the columns. In this sector moulds are relatively small, but they are often equipped with internal sliding beds that are driven by very long auxiliary cylinders, considerably increasing the total dimensions of the mould overall.

Therefore, the MIL/COMPACT series provides significant benefits:

- Carrying out adjusting operations on a smaller and therefore cheaper press with subsequent reduction of the investment amortization period;

- Handling of moulds with very long auxiliary cylinders without the need to disassemble them, providing substantial time-saving gains;

- Possibility to design the plate exit on the backside with special travels.

Standard movements of the platens

For optimal access to the mould, the press upper plate can be tilted forward by 100°.

By tilting the press plate on the short side, the operator can work at an optimal height, normally standing, without having to use unstable ladders, platforms or lifting equipment, which are often necessary in case of presses with long side rotation.

Moreover, with tilting rotation on the short side, the overall press height is considerably reduced.

The lower plate is hydraulically extensible, sliding on the base guided by ball bearings.

In the final position, the plate comes down and is held by means of 8 hydraulic cylinders, thus completely leaning on specific ground support bands.

The system guarantees high repeatability accuracy equal to ± 0,04 mm.

It allows to draw the lower part of the die or mould out of the press into an effortless working position

All functions are comfortably performed from the touch panel.

MIL Classic series. Models

- MIL 122-123 (1200x1000 mm)

- MIL 142-143 (1400x1200 mm)

- MIL 162-163 (1600x1300 mm)

- MIL 202-203 (2000x1500 mm)

- MIL 252-253 (2500x1700 mm)

- MIL 262-263 (2500x2000 mm)

- MIL 302-303-304 (3000x2000 mm)

- MIL 305 (3000x2400 mm)

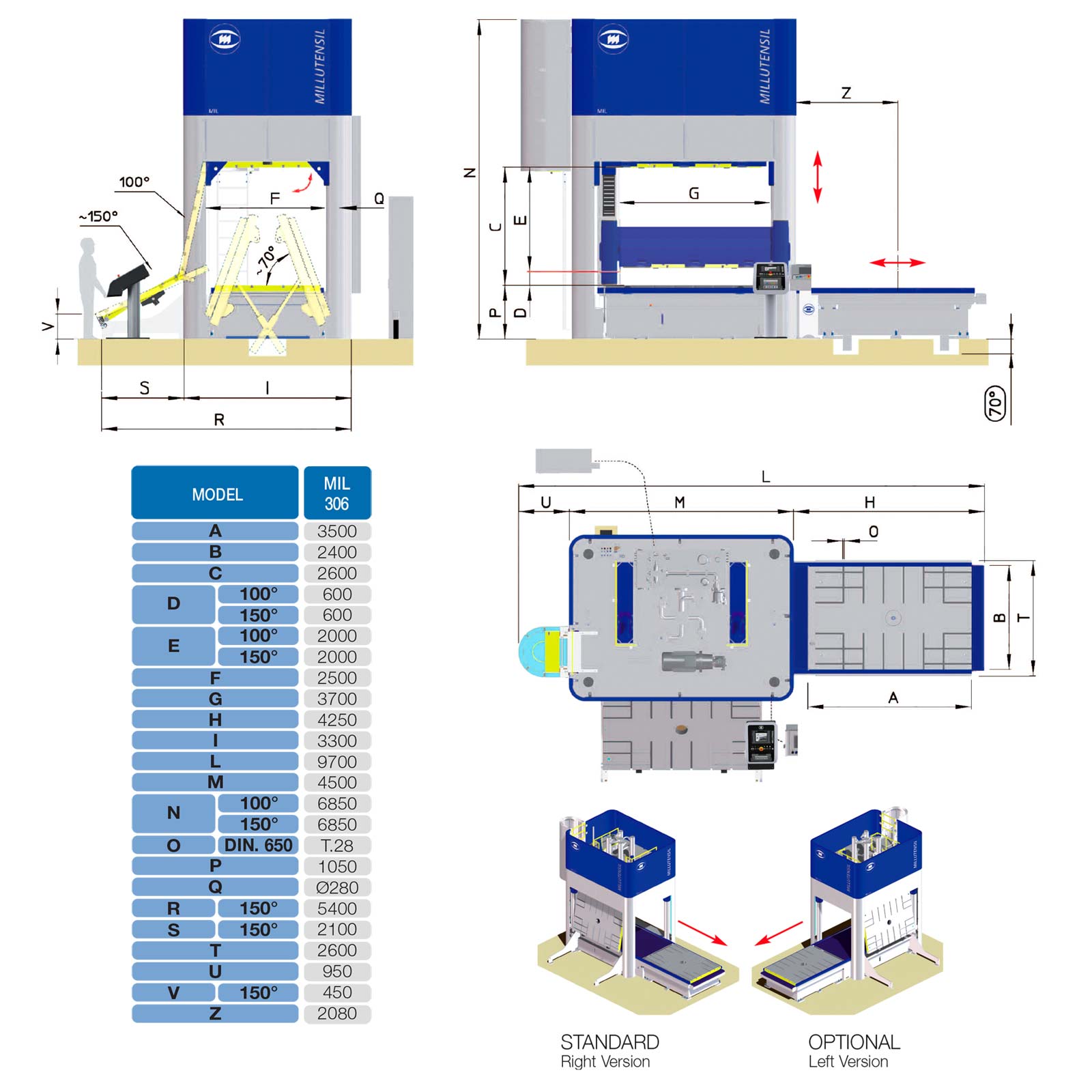

- MIL 306 (3500x2400 mm)

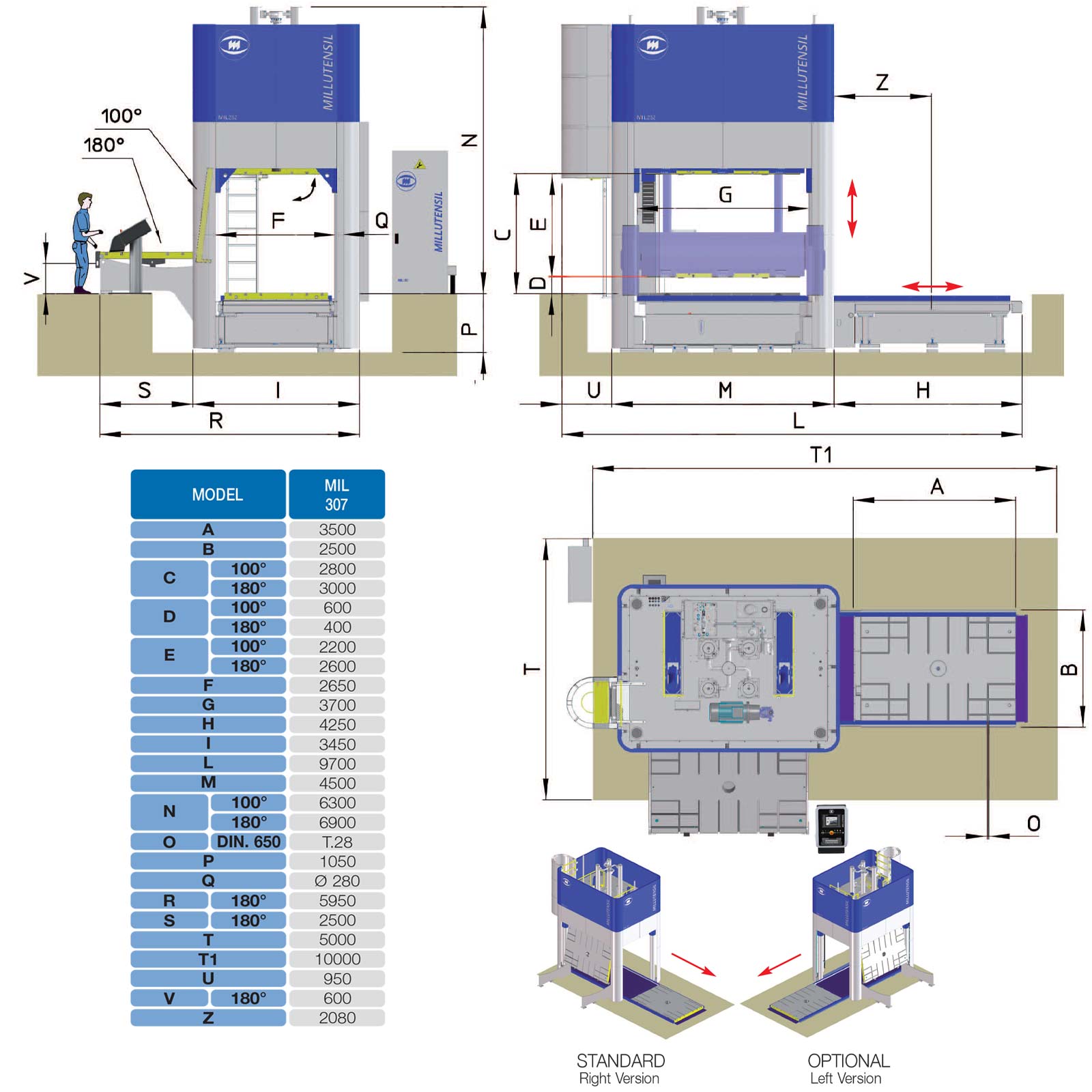

- MIL 307 (3500x2500 mm)

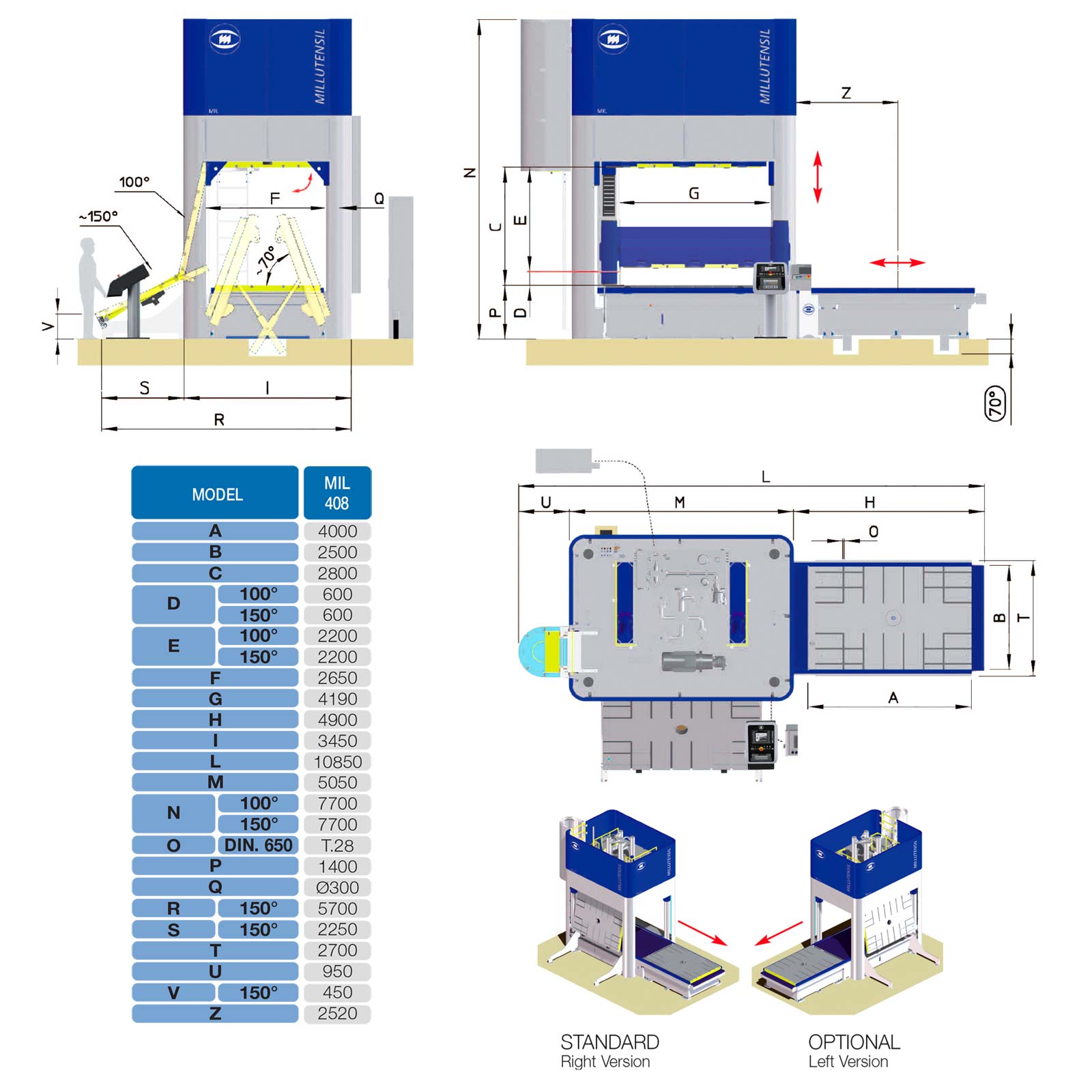

- MIL 408 (4000x2500 mm)

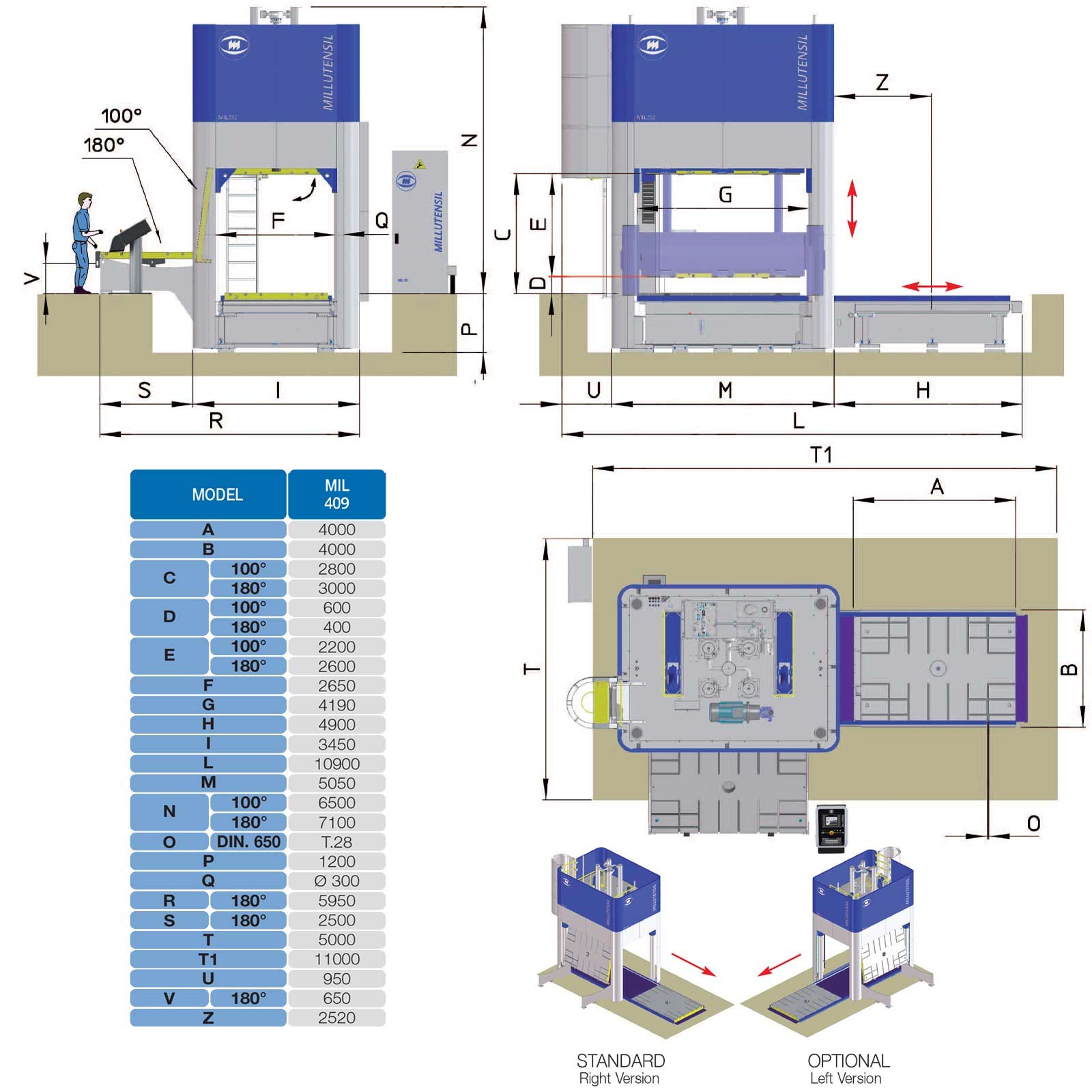

- MIL 409 (4000x4000 mm)

- MIL 509 (5000x2500 mm)

The smallest version of the MIL series

The press is produced in two models, MIL 122 – MIL 123, which differ in performance. The press is available only in floor version.

Both models are equipped with user-friendly graphics control panel, monitored through Siemens PLC commanded by Touch Panel installed in a pulpit station.

Platen dimensions are 1.200×1.000 mm (47X39 inches).

| Model | MIL 122 | MIL 123 |

|---|---|---|

| Max. clamping force | 600 kN | 800 kN |

| Max. opening force | 120 kN | 170 kN |

| Max. load capacity on lower plate | 6.000 kg | 7.000 kg |

| Max. load capacity on upper plate | 3.000 kg | 3.500 kg |

The MIL 122 and MIL 123 models are offered in floor version only. They can also be equipped with all optional accessories.

The MIL series version for medium size moulds

The press is produced in two models, MIL 142 – MIL 143, which differ in performance. The press is available only in floor version.

Both models are equipped with user-friendly graphics control panel, monitored through Siemens PLC commanded by Touch Panel installed in a pulpit station.

Platen dimensions are 1.400×1.200 mm (55X47 inches).

| Model | MIL 142 | MIL 143 |

|---|---|---|

| Max. clamping force | 700 kN | 1.000 kN |

| Max. opening force | 180 kN | 220 kN |

| Max. load capacity on lower plate | 8.000 kg | 10.000 kg |

| Max. load capacity on upper plate | 4.000 kg | 5.000 kg |

The MIL 142 and MIL 143 models are offered in floor version only. They can also be equipped with all optional accessories.

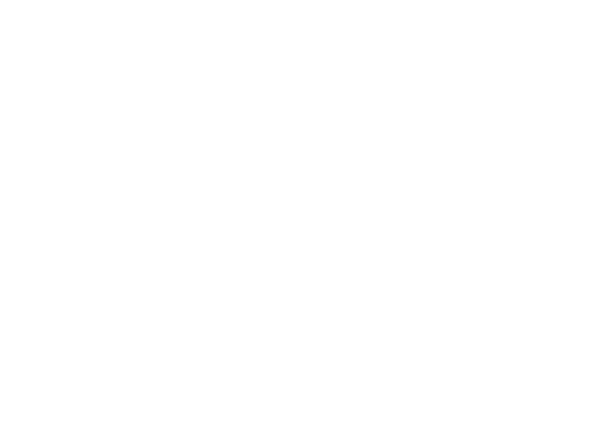

The MIL series version for medium size moulds

The press is produced in two models, MIL 162 – MIL 163, which differ in performance. The press is available only in floor version.

Both models are equipped with user-friendly graphics control panel, monitored through Siemens PLC commanded by Touch Panel installed in a pulpit station.

Platen dimensions are 1.600×1.300 mm (63X51 inches).

| Model | MIL 162 | MIL 163 |

|---|---|---|

| Max. clamping force | 1.000 kN | 1.500 kN |

| Max. opening force | 250 kN | 300 kN |

| Max. load capacity on lower plate | 16.000 kg | 16.000 kg |

| Max. load capacity on upper plate | 10.000 kg | 15.000 kg |

The MIL 162 and MIL 163 models are offered in floor version only. They can also be equipped with all optional accessories.

The MIL series version for medium size moulds

The press is produced in two models, MIL 202- MIL 203, which differ in performance. The press is available only in floor version.

Both models are equipped with user-friendly graphics control panel, monitored through Siemens PLC commanded by Touch Panel installed in a pulpit station.

Platen dimensions are 2.000×1.500 mm (78X59 inches).

| Model | MIL 202 | MIL 203 |

|---|---|---|

| Max. clamping force | 1.200 kN | 1.500 kN |

| Max. opening force | 300 kN | 350 kN |

| Max. load capacity on lower plate | 30.000 kg | 30.000 kg |

| Max. load capacity on upper plate | 10.000 kg | 15.000 kg |

The MIL 202 and MIL 203 models are offered in floor version only. They can also be equipped with all optional accessories.

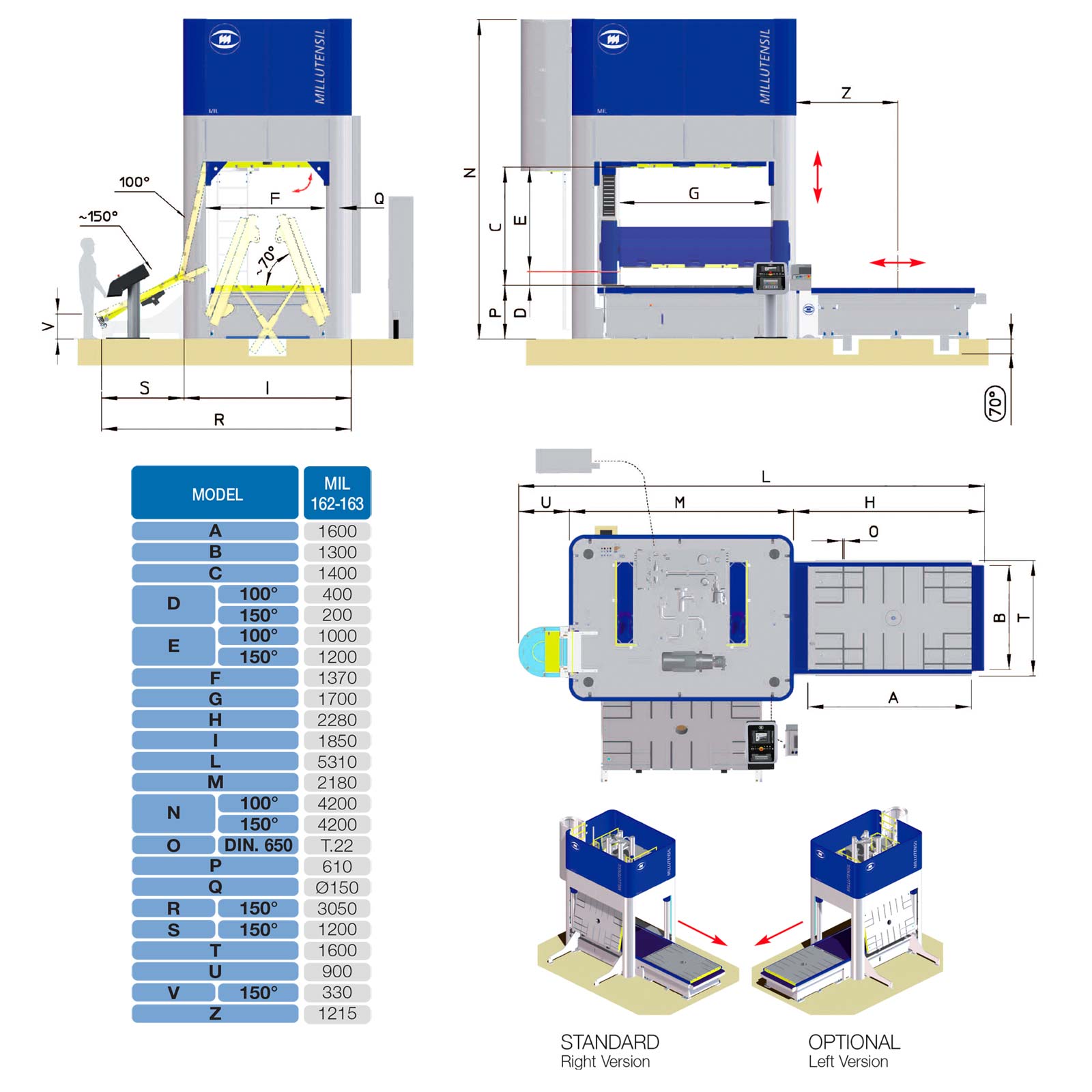

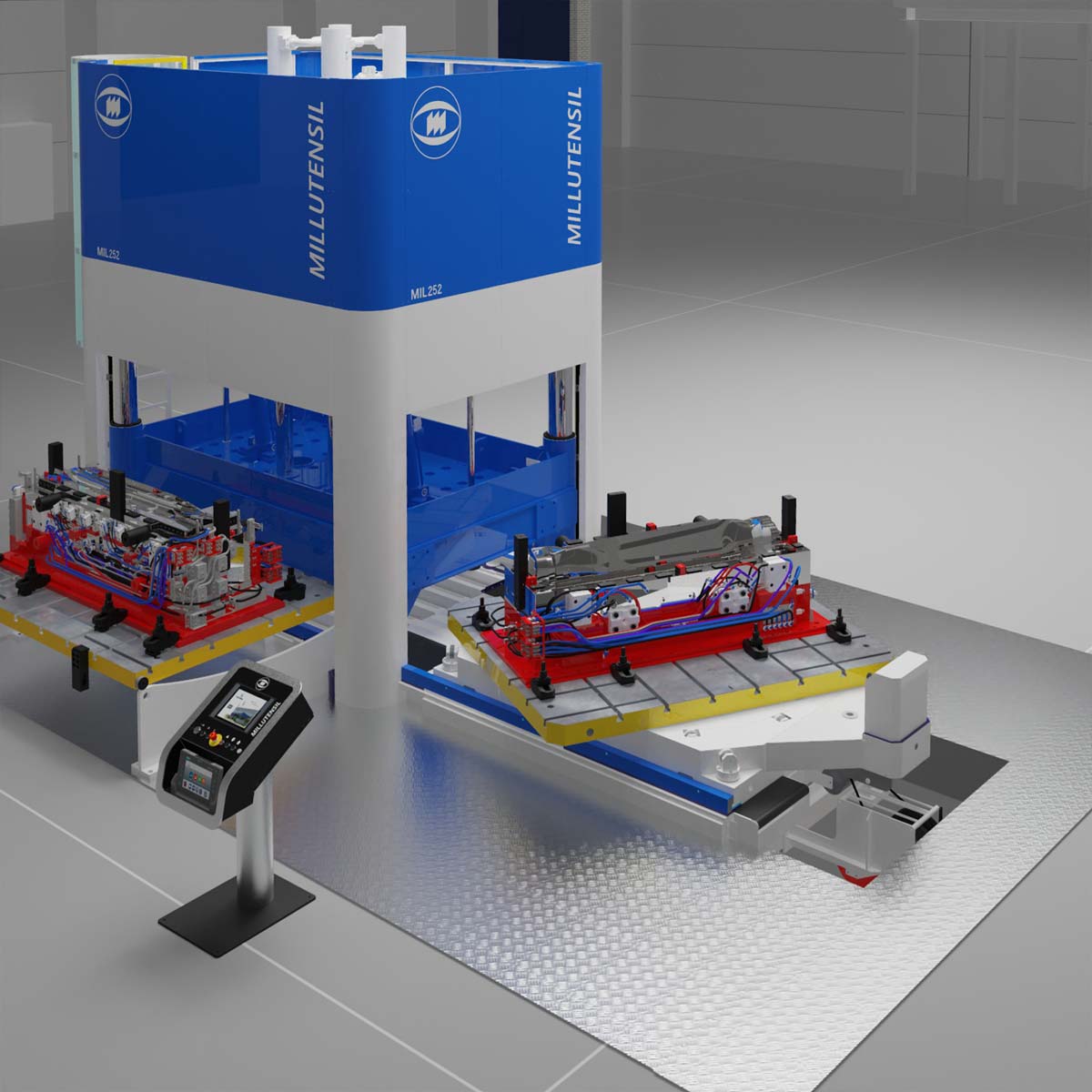

The MIL series version for medium and large size moulds

The press is produced in two models, MIL 252 – 253, which differ in performance. They are both available in the floor version and in the pit version.

Both models are equipped with user-friendly graphics control panel, monitored through Siemens PLC commanded by Touch Panel installed in a pulpit station.

Platen dimensions are 2.500×1.700 mm (98X67 inches).

| Model | MIL 252 | MIL 253 |

|---|---|---|

| Max. clamping force | 1.500 kN | 2.000 kN |

| Max. opening force | 450 kN | 550 kN |

| Max. load capacity on lower plate | 40.000 kg | 40.000 kg |

| Max. load capacity on upper plate | 12.000 kg | 18.000 kg |

The MIL 252 and MIL 253 models are offered in both floor and pit version. They can also be equipped with all optional accessories except the energy accumulator and the wax injection unit.

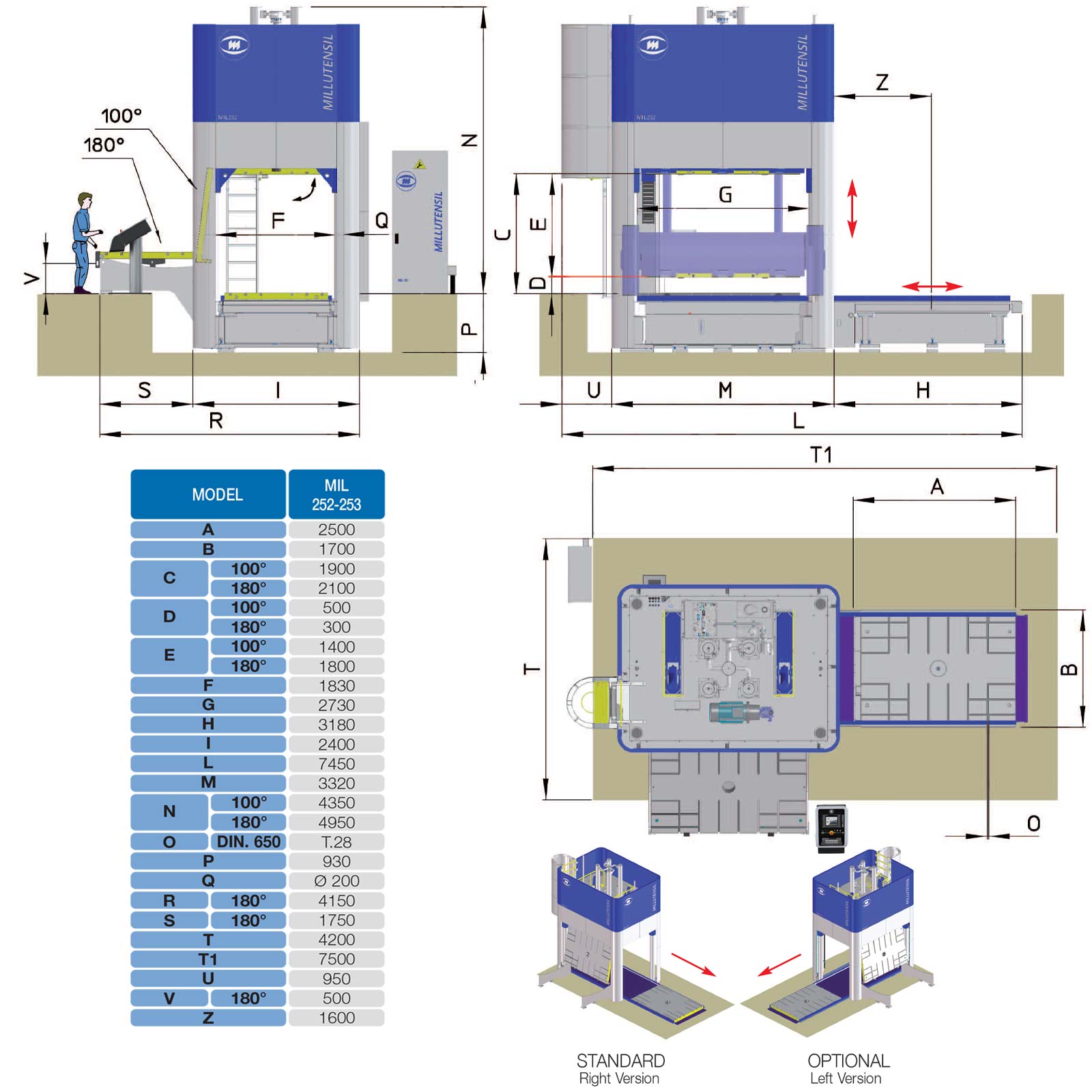

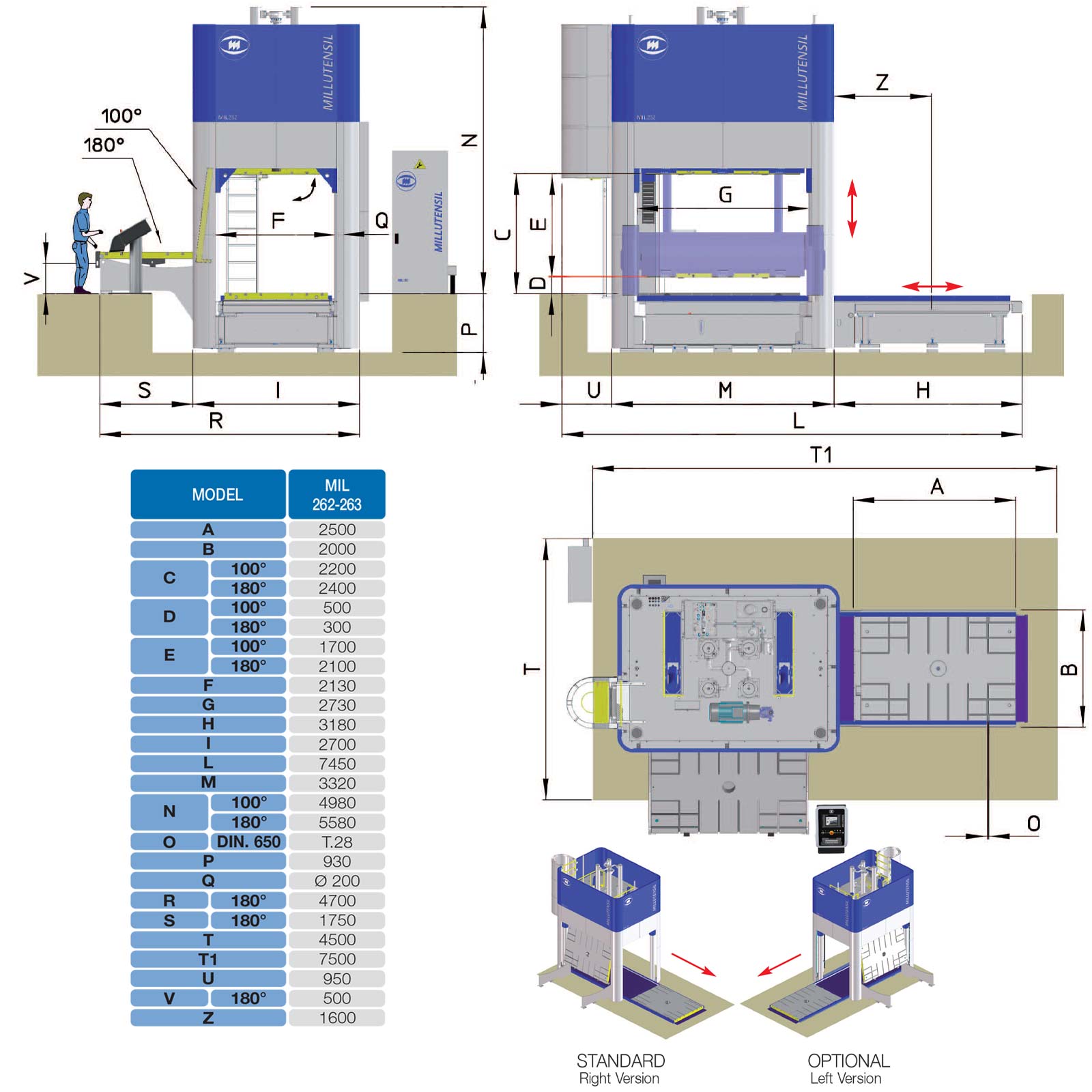

The MIL series version for medium and large size moulds

The press is produced in two models, MIL 262 – 263, which differ in performance. They are both available in the floor version and in the pit version.

Both models are equipped with user-friendly graphics control panel, monitored through Siemens PLC commanded by Touch Panel installed in a pulpit station.

Platen dimensions are 2.500×2.000 mm (98X67 inches).

| Model | MIL 262 | MIL 263 |

|---|---|---|

| Max. clamping force | 1.500 kN | 2.000 kN |

| Max. opening force | 450 kN | 550 kN |

| Max. load capacity on lower plate | 45.000 kg | 45.000 kg |

| Max. load capacity on upper plate | 18.000 kg | 20.000 kg |

The MIL 262 and MIL 263 models are offered in both floor and pit version. They can also be equipped with all optional accessories except the energy accumulator and the wax injection unit.

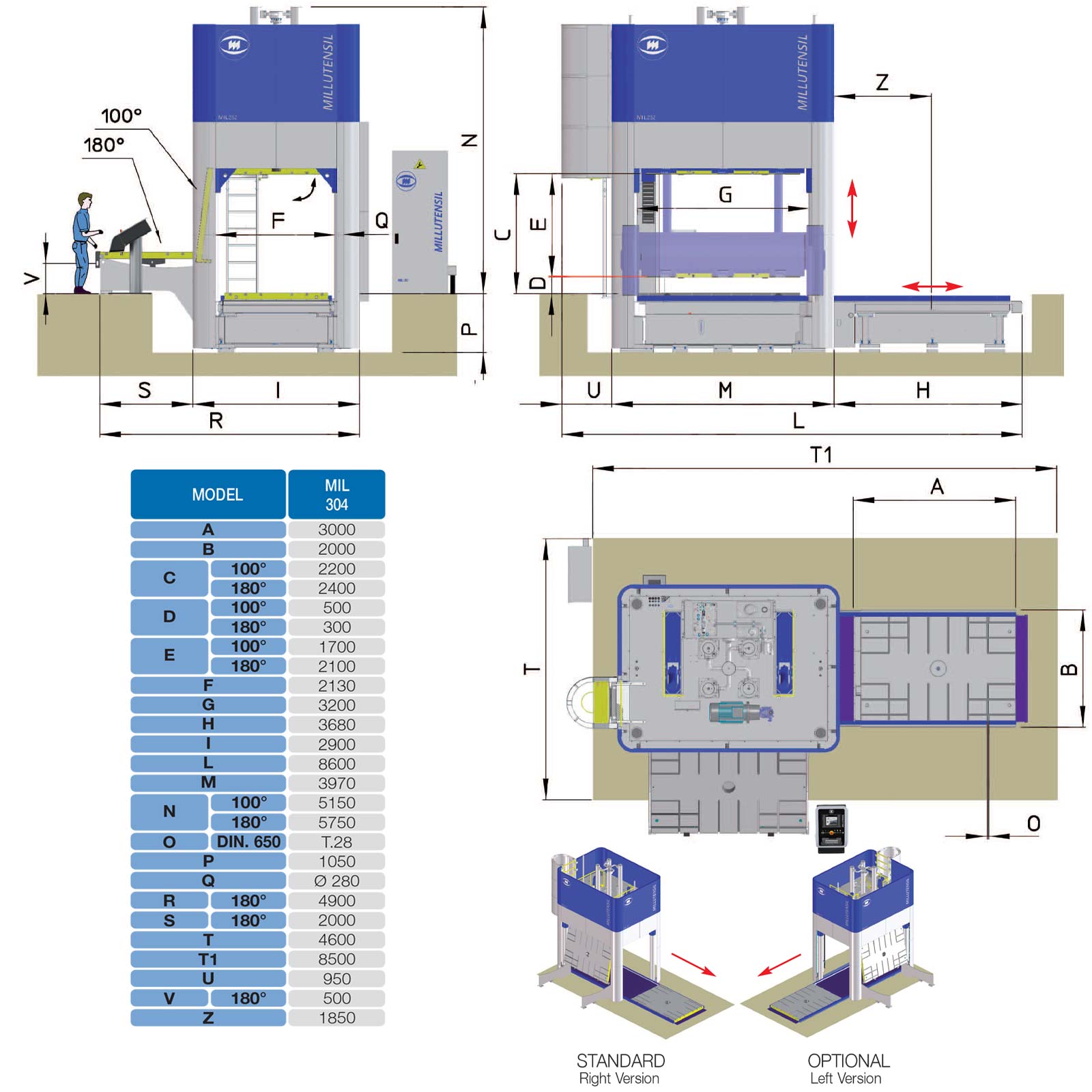

The MIL series version for large size moulds

The press is produced in three models, MIL 302 – MIL 303 – MIL 304, which differ in performance. They are both available in the floor version and in the pit version.

All models are equipped with user-friendly graphics control panel, monitored through Siemens PLC commanded by Touch Panel installed in a pulpit station.

Platen dimensions are 3.000×2.000 mm (118×78 inches).

| MIL 302 | MIL 303 | MIL 304 | |

|---|---|---|---|

| Max. clamping force | 2.500 kN | 3.000 kN | 4.000 kN |

| Max. opening force | 700 kN | 800 kN | 850 kN |

| Max. load capacity on lower plate | 70.000 kg | 70.000 kg | 70.000 kN |

| Max. load capacity on upper plate | 25.000 kg | 30.000 kg | 30.000 kN |

The MIL 302 – MIL 303 and MIL 304 models are offered in both floor and pit version. They can also be equipped with all optional accessories except the energy accumulator, the wax injection unit.

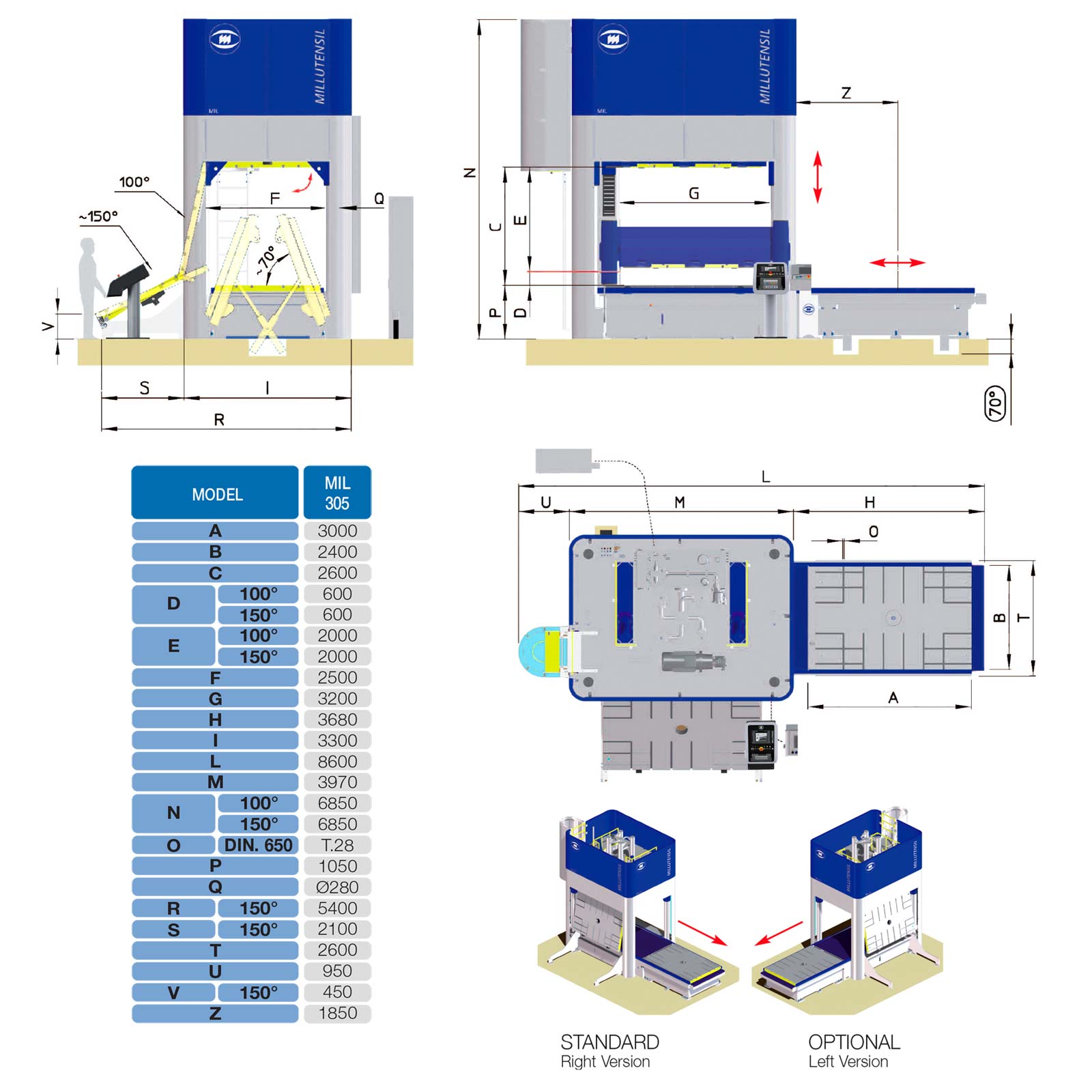

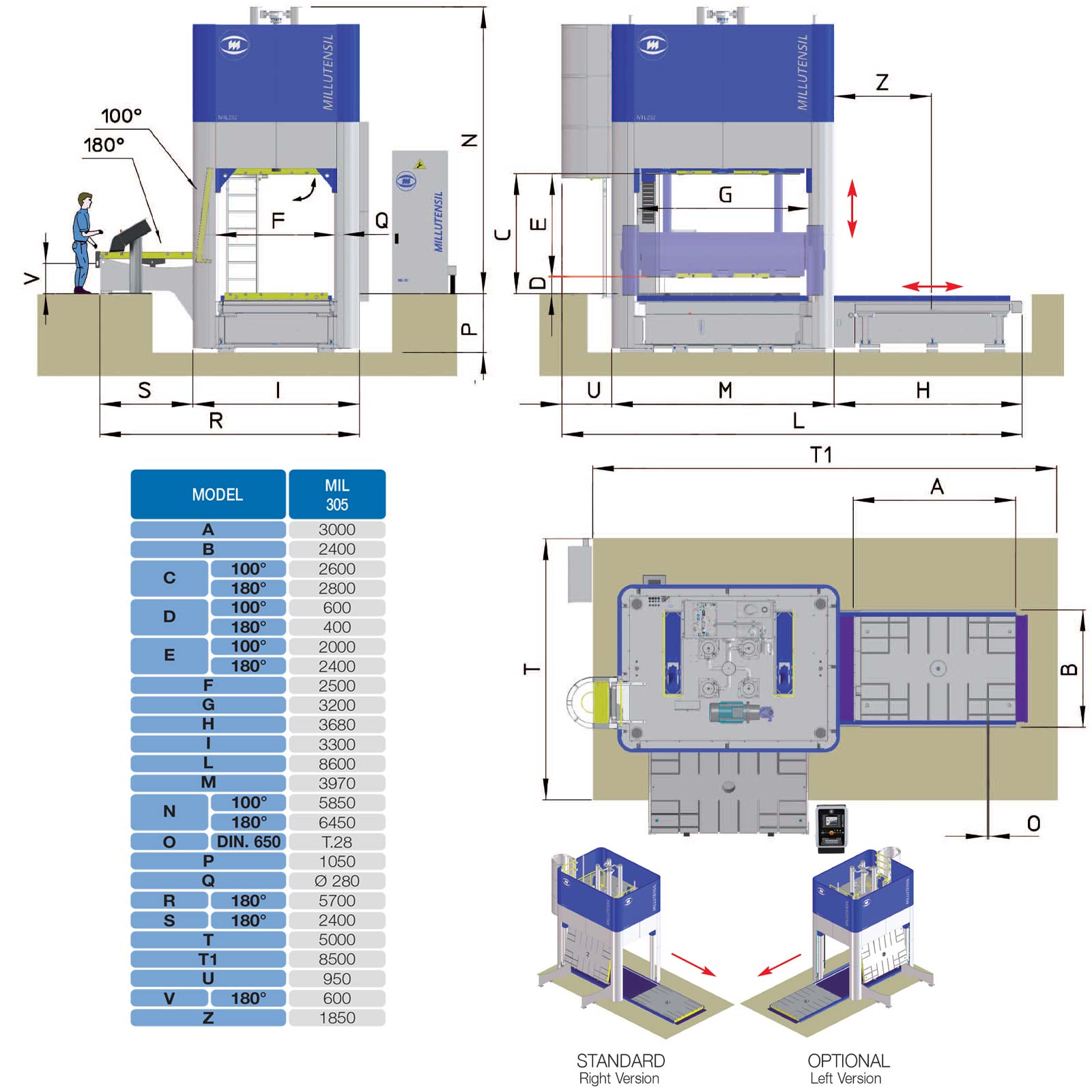

The MIL series version for large size moulds

The MIL 305 spotting press is available in the floor version and in the pit version. The max clamping force, 4.000 kN, can optionally be increased to 5.000 kN.

The press is equipped with user-friendly graphics control panel, monitored through Siemens PLC commanded by Touch Panel installed in a pulpit station.

Platen dimensions are 3.000×2.400 mm (118×84 inches).

| Model | MIL 305 |

|---|---|

| Max. clamping force | 4.000 / 5.000 kN |

| Max. opening force | 900 kN |

| Max. load capacity on lower plate | 75.000 kg |

| Max. load capacity on upper plate | 30.000 kg |

The MIL 305 model is offered in both floor and pit version. It can also be equipped with all optional accessories except the energy accumulator, the wax injection unit.

The MIL series version for large size moulds

The MIL 306 spotting press is available in the floor version and in the pit version. The max clamping force, 4.000 kN, can optionally be increased to 5.000 kN.

The press is equipped with user-friendly graphics control panel, monitored through Siemens PLC commanded by Touch Panel installed in a pulpit station.

Platen dimensions are 3.500×2.400 mm (137×94 inches).

| Model | MIL 306 |

|---|---|

| Max. clamping force | 4.000 / 5.000 kN |

| Max. opening force | 1000 kN |

| Max. load capacity on lower plate | 80.000 kg |

| Max. load capacity on upper plate | 40.000 kg |

The MIL 306 model is offered in both floor and pit version. It can also be equipped with all optional accessories except the energy accumulator, the wax injection unit.

The MIL series version for large size moulds

The MIL 307 spotting press is available in the floor version and in the pit version. The max clamping force, 4.000 kN, can optionally be increased to 5.000 kN.

The press is equipped with user-friendly graphics control panel, monitored through Siemens PLC commanded by Touch Panel installed in a pulpit station.

Platen dimensions are 3.500×2.500 mm (137×98 inches).

| Model | MIL 307 |

|---|---|

| Max. clamping force | 4.000 / 5.000 kN |

| Max. opening force | 1000 kN |

| Max. load capacity on lower plate | 80.000 kg |

| Max. load capacity on upper plate | 40.000 kg |

The MIL 307 model is offered in both floor and pit version. It can also be equipped with all optional accessories except the energy accumulator, the wax injection unit.

The MIL series version for large size moulds

The MIL 408 spotting press is available in the floor version and in the pit version. The max clamping force, 4.000 kN, can optionally be increased to 5.000 kN.

The press is equipped with user-friendly graphics control panel, monitored through Siemens PLC commanded by Touch Panel installed in a pulpit station.

Platen dimensions are 4.000×2.500 mm (157×98 inches).

| Model | MIL 408 |

|---|---|

| Max. clamping force | 4.000 / 5.000 kN |

| Max. opening force | 1.500 kN |

| Max. load capacity on lower plate | 100.000 kg |

| Max. load capacity on upper plate | 40.000 kg |

The MIL 408 model is offered in both floor and pit version.It can also be equipped with all optional accessories except the energy accumulator, the wax injection unit.

The MIL series version for large size moulds

The MIL 409 spotting press is available in the floor version and in the pit version. The max clamping force, 5.000 kN, can optionally be increased to 6.000 kN.

The press is equipped with user-friendly graphics control panel, monitored through Siemens PLC commanded by Touch Panel installed in a pulpit station.

Platen dimensions are 4.000×4.000 mm (157×157 inches).

| Model | MIL 409 |

|---|---|

| Max. clamping force | 5.000 / 6.000 kN |

| Max. opening force | 1.500 kN |

| Max. load capacity on lower plate | 130.000 kg |

| Max. load capacity on upper plate | 60.000 kg |

The MIL 409 model is offered in both floor and pit version.It can also be equipped with all optional accessories except the energy accumulator, the wax injection unit.

The MIL series version for large size moulds

The MIL 509 spotting press is available in the floor version and in the pit version. The max clamping force, 4.000 kN, can optionally be increased to 5.000 kN.

The press is equipped with user-friendly graphics control panel, monitored through Siemens PLC commanded by Touch Panel installed in a pulpit station.

Platen dimensions are 5.000×2.500 mm (196×98 inches).

| Model | MIL 509 |

|---|---|

| Max. clamping force | 4.000 / 5.000 kN |

| Max. opening force | 1.500 kN |

| Max. load capacity on lower plate | 100.000 kg |

| Max. load capacity on upper plate | 40.000 kg |

The MIL 509 model is offered in both floor and pit version.It can also be equipped with all optional accessories except the energy accumulator, the wax injection unit.

MIL Compact series. Models

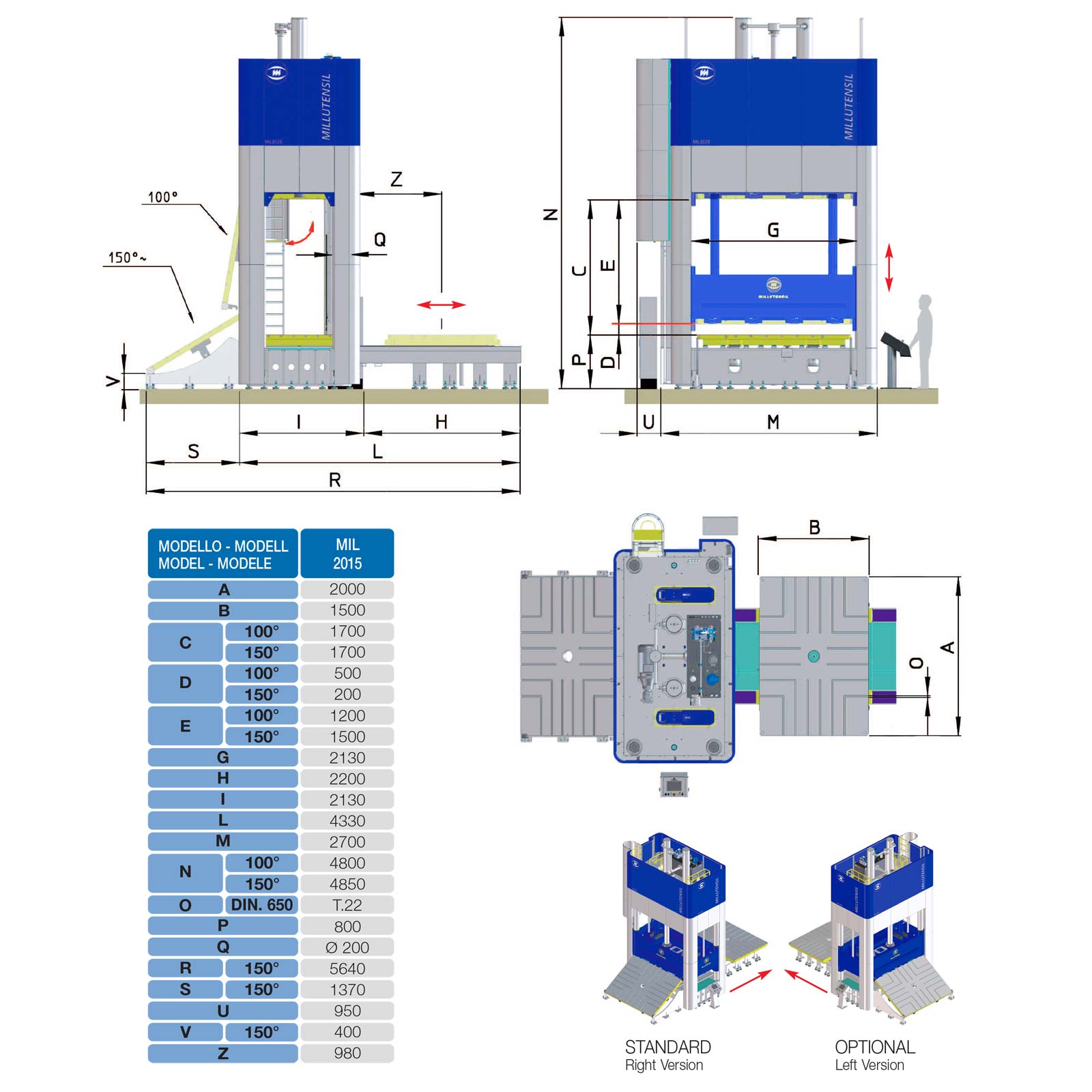

The smallest version of the MIL Compact series

The press is available only in floor version.

The press is equipped with user-friendly graphics control panel, monitored through Siemens PLC commanded by Touch Panel installed in a pulpit station.

Platen dimensions are 2.000×1.500 mm (78×59 inches).

| Model | MIL 2015 |

|---|---|

| Max. clamping force | 1.200 kN |

| Max. opening force | 350 kN |

| Max. load capacity on lower plate | 30.000 kg |

| Max. load capacity on upper plate | 15.000 kg |

Optionally the max. clamping force can be increased to 1.500 kN. The press can also be equipped with all optional accessories.

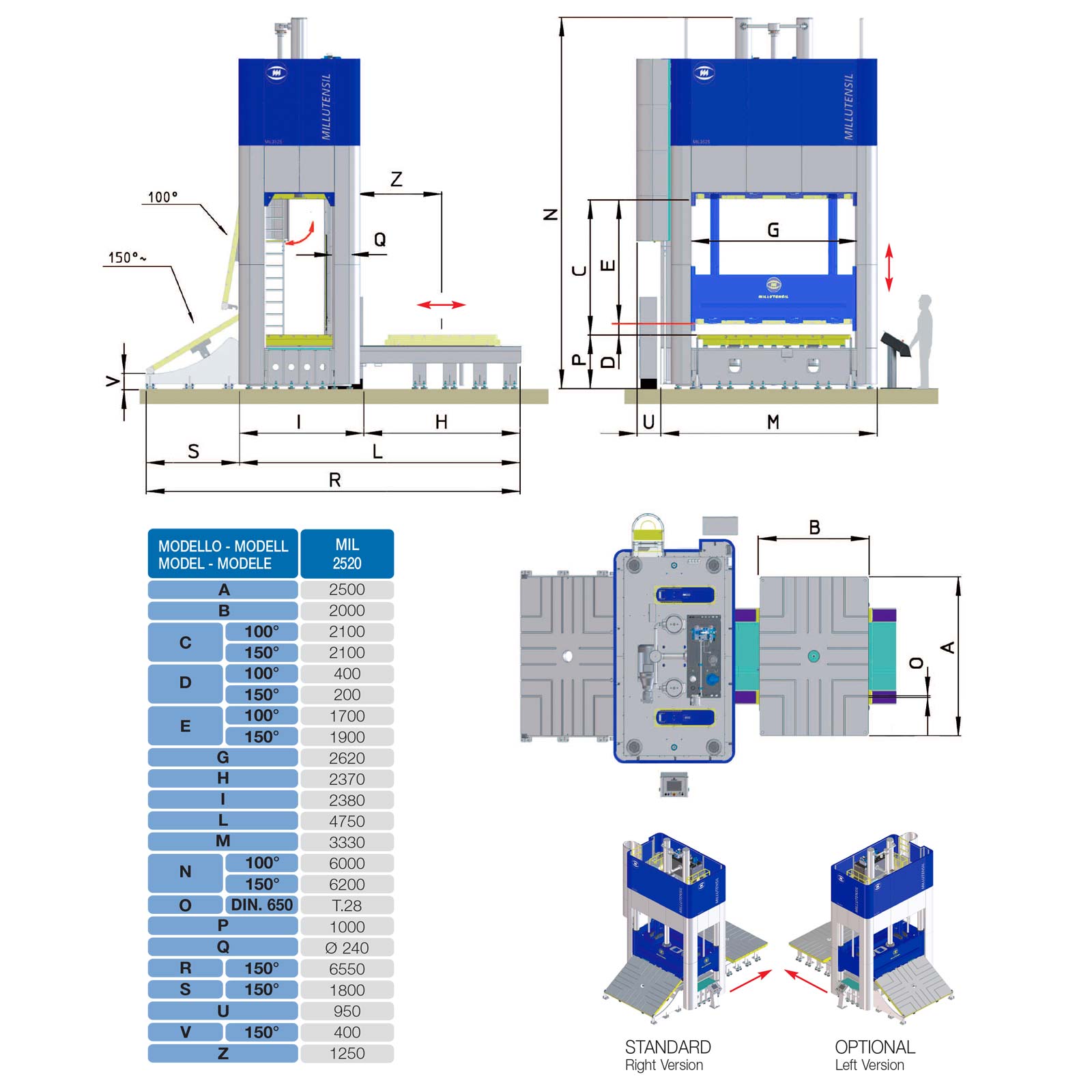

The MIL Compact series version for medium and large size moulds

The press is available in both floor and pit version.

The press is equipped with user-friendly graphics control panel, monitored through Siemens PLC commanded by Touch Panel installed in a pulpit station.

Platen dimensions are 2.500×2.000 mm (98×78 inches).

| Model | MIL 2025 |

|---|---|

| Max. clamping force | 1.500 kN |

| Max. opening force | 550 kN |

| Max. load capacity on lower plate | 45.000 kg |

| Max. load capacity on upper plate | 18.000 kg |

Optionally the max. clamping force can be increased to 2.000 kN.

The press can be equipped with all optional accessories except the energy accumulator and the wax injection unit.

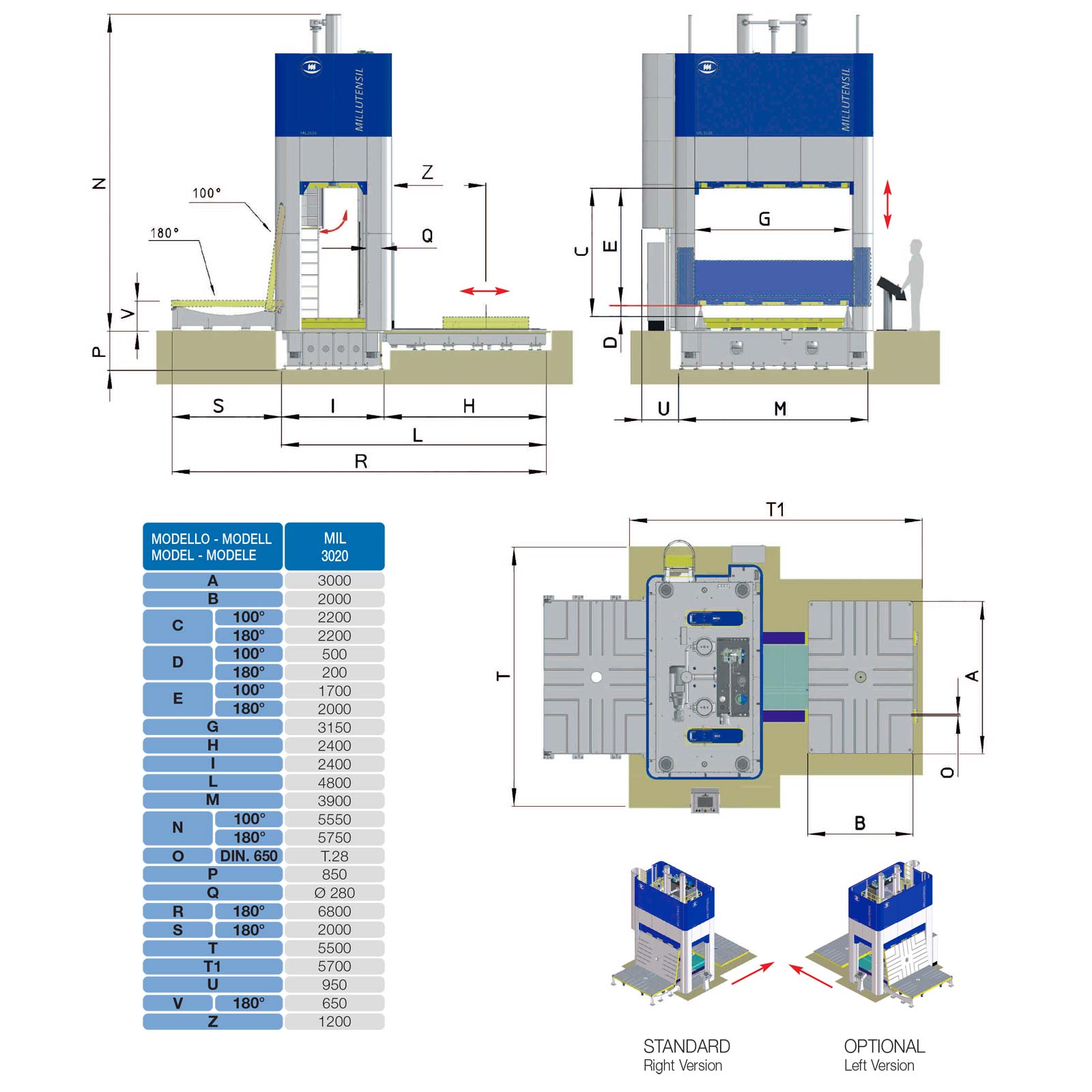

The MIL Compact series version for large size moulds

The press is available in both floor and pit version.

The press is equipped with user-friendly graphics control panel, monitored through Siemens PLC commanded by Touch Panel installed in a pulpit station.

Platen dimensions are 3.000×2.000 mm (118×78 inches).

| Model | MIL 3020 |

|---|---|

| Max. clamping force | 2.500 kN |

| Max. opening force | 900 kN |

| Max. load capacity on lower plate | 48.000 kg |

| Max. load capacity on upper plate | 20.000 kg |

Optionally the max. clamping force can be increased to 3.000 kN.

The press can be equipped with all optional accessories except the energy accumulator and the wax injection unit.

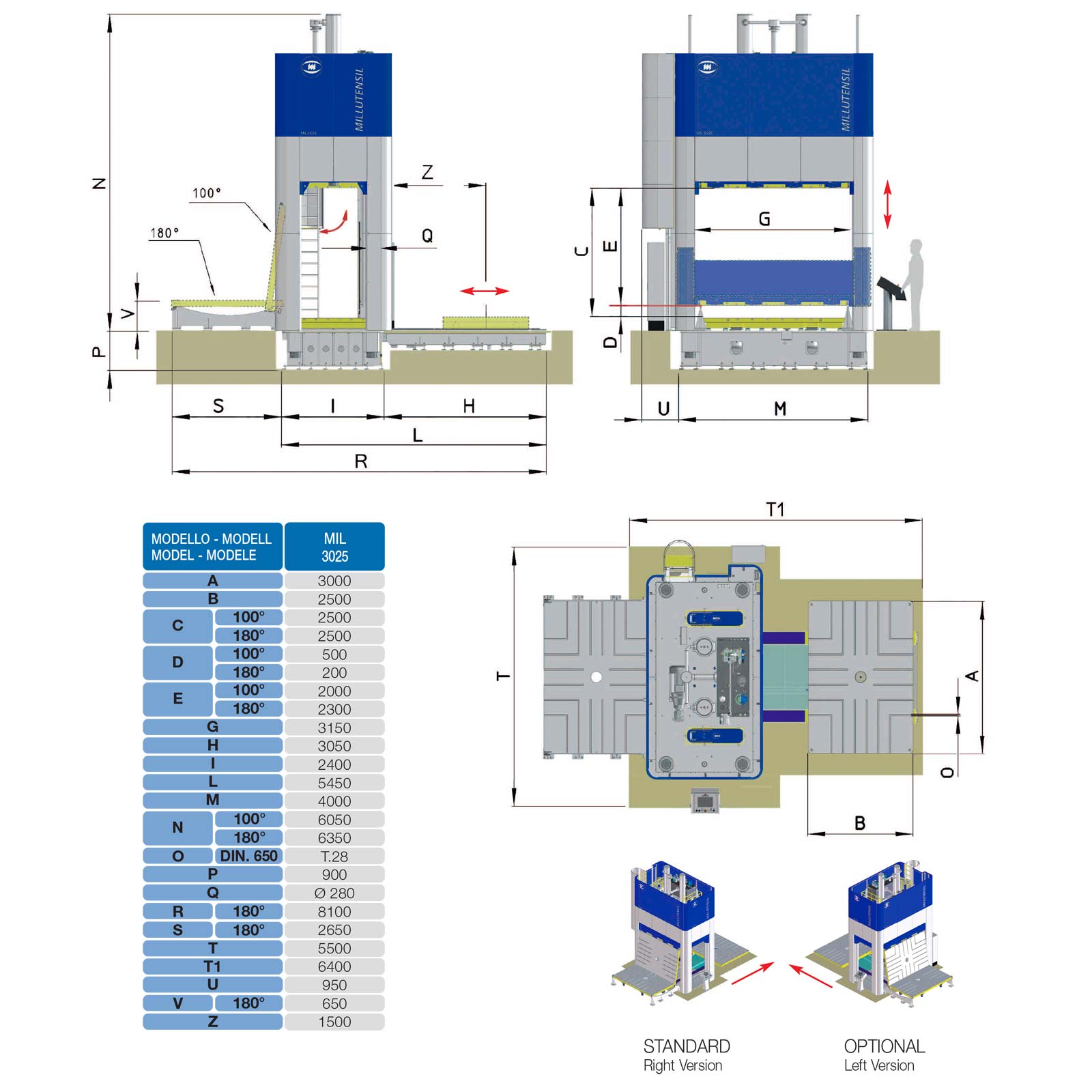

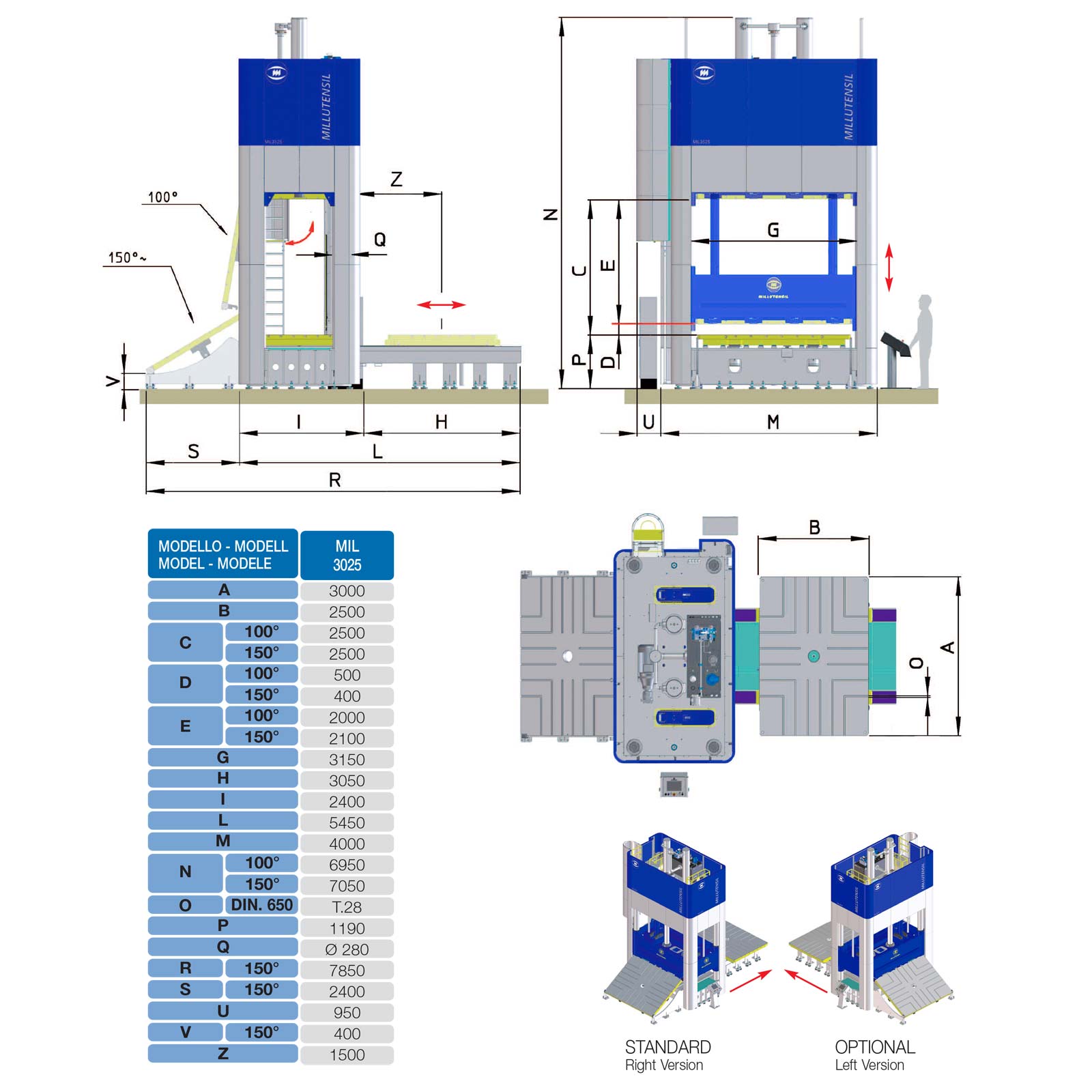

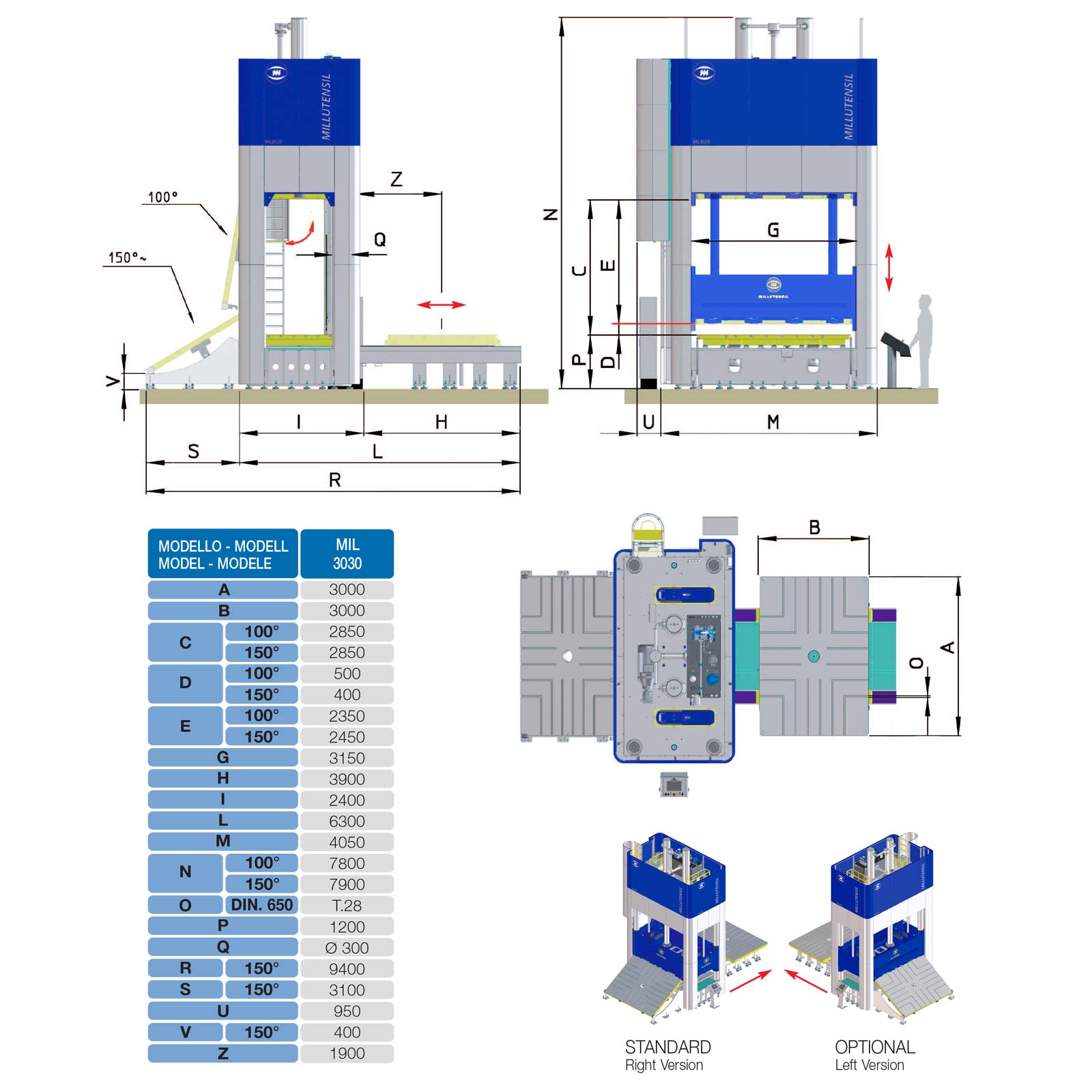

The MIL Compact series version for large size moulds

The press is available in both floor and pit version.

The press is equipped with user-friendly graphics control panel, monitored through Siemens PLC commanded by Touch Panel installed in a pulpit station.

Platen dimensions are 3.000×2.500 mm (118×98 inches).

| Model | MIL 3025 |

|---|---|

| Max. clamping force | 2.500 kN |

| Max. opening force | 900 kN |

| Max. load capacity on lower plate | 50.000 kg |

| Max. load capacity on upper plate | 22.000 kg |

Optionally the max. clamping force can be increased to 3.000 kN.

The press can be equipped with all optional accessories except the energy accumulator and the wax injection unit.

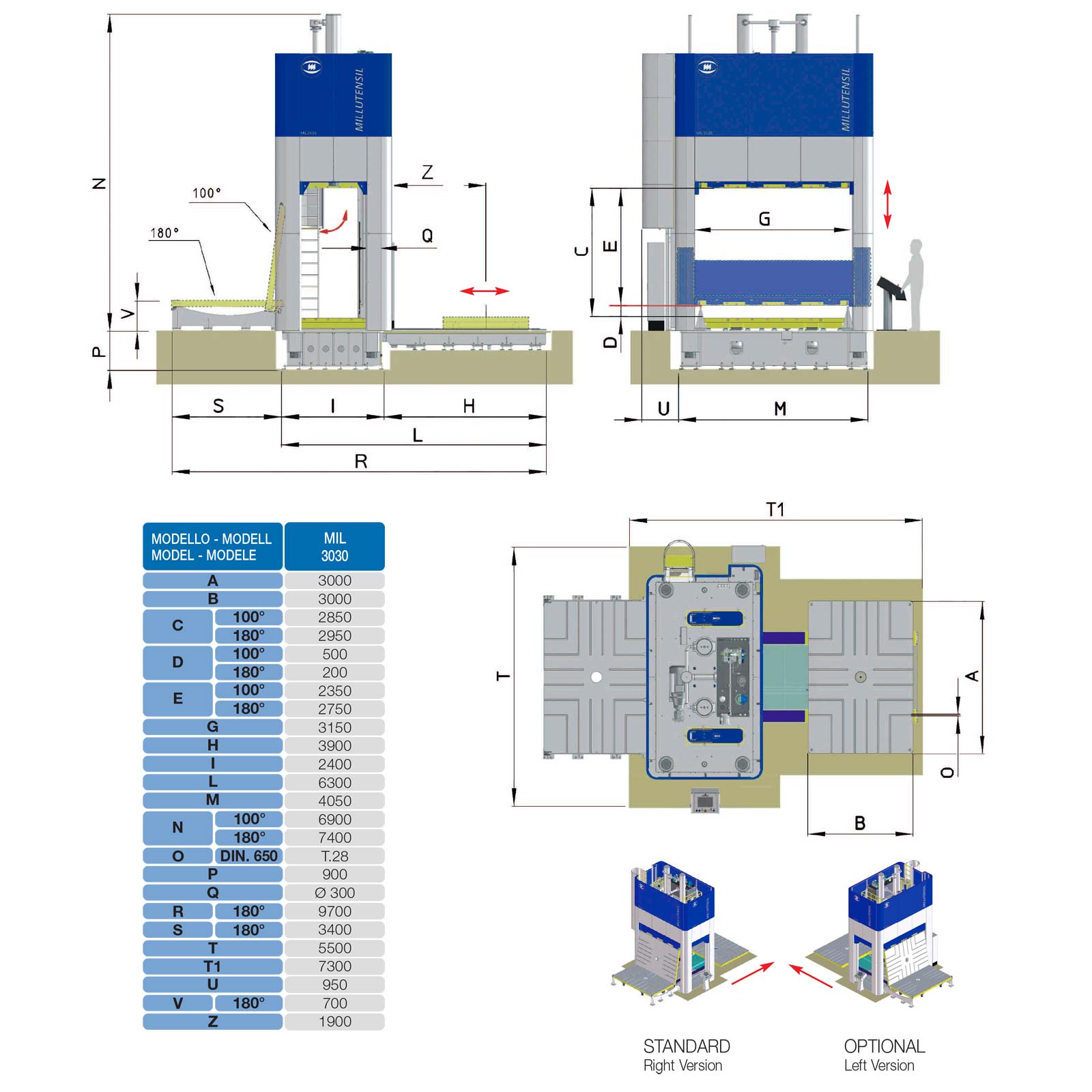

The MIL Compact series version for large size moulds

The press is available in both floor and pit version.

The press is equipped with user-friendly graphics control panel, monitored through Siemens PLC commanded by Touch Panel installed in a pulpit station.

Platen dimensions are 3.000×3.000 mm (118×118 inches).

| Model | MIL 3030 |

|---|---|

| Max. clamping force | 3000 kN |

| Max. opening force | 1000 kN |

| Max. load capacity on lower plate | 60.000 kg |

| Max. load capacity on upper plate | 30.000 kg |

Optionally the max. clamping force can be increased to 4.000 kN.

The press can be equipped with all optional accessories except the energy accumulator and the wax injection unit.

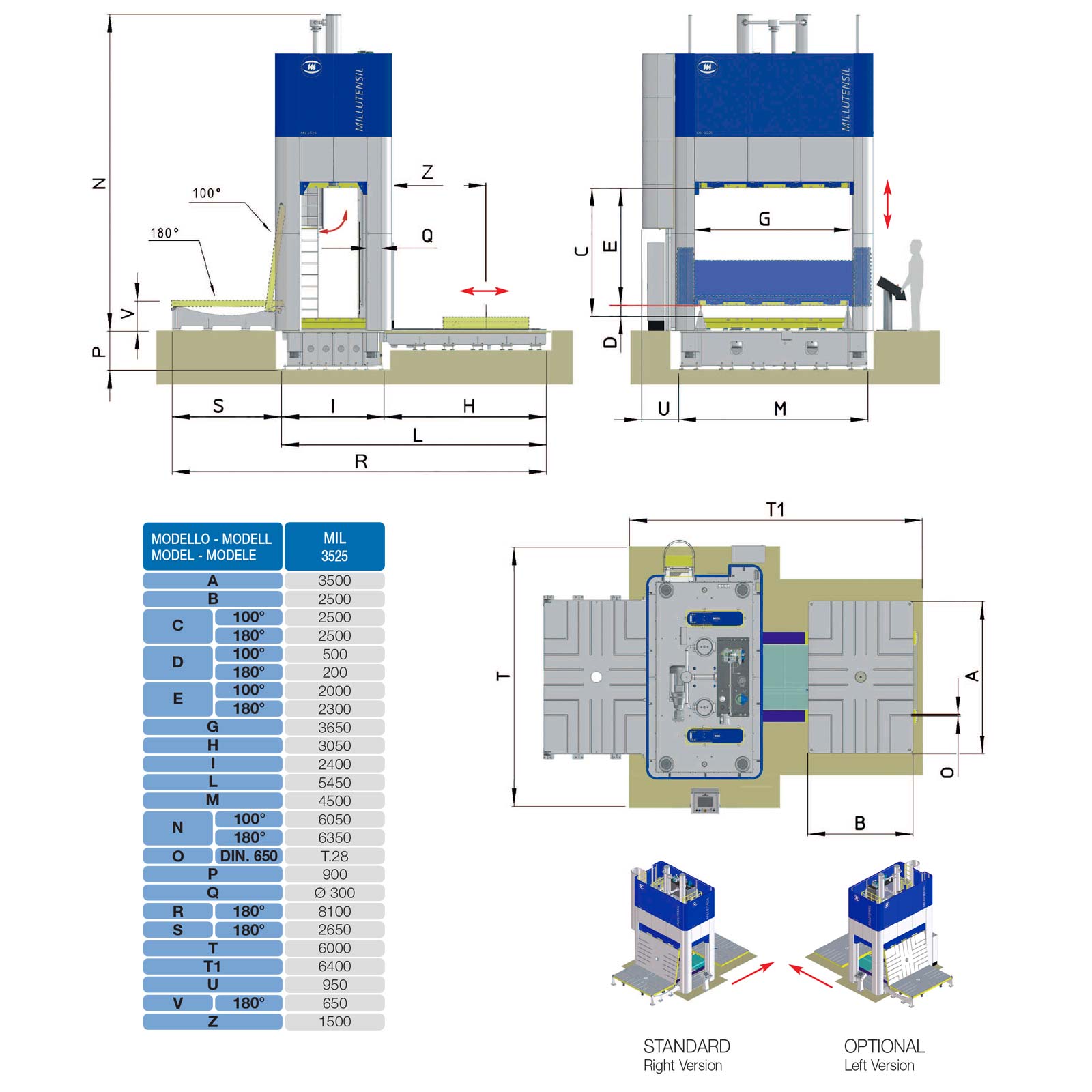

The MIL Compact series version for large size moulds

The press is available in both floor and pit version.

The press is equipped with user-friendly graphics control panel, monitored through Siemens PLC commanded by Touch Panel installed in a pulpit station.

Platen dimensions are 3.500×2.500 mm (137×98 inches).

| Model | MIL 3525 |

|---|---|

| Max. clamping force | 3.000 kN |

| Max. opening force | 1000 kN |

| Max. load capacity on lower plate | 55.000 kg |

| Max. load capacity on upper plate | 25.000 kg |

Optionally the max. clamping force can be increased to 4.000 kN.

The press can be equipped with all optional accessories except the energy accumulator and the wax injection unit.

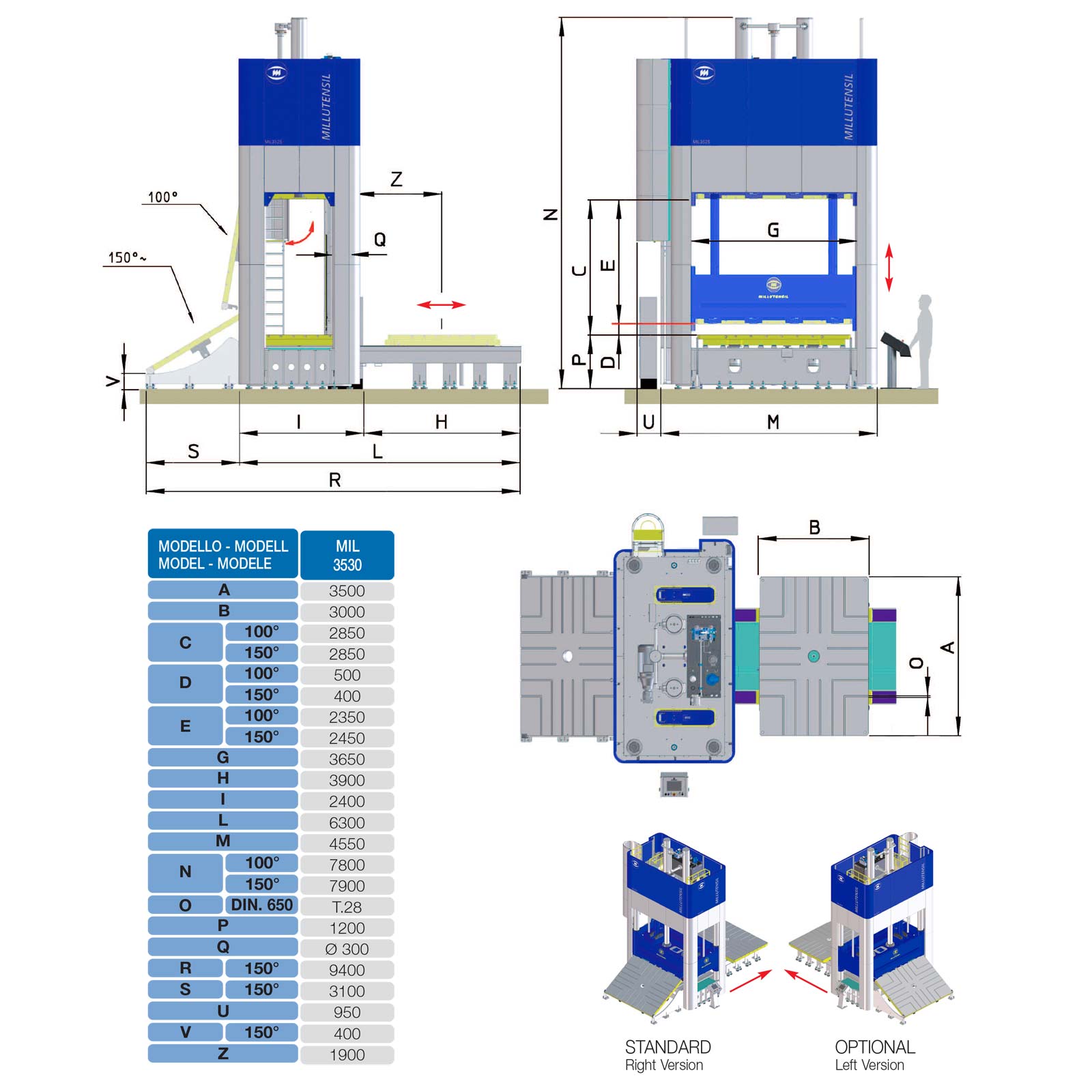

The MIL Compact series version for large size moulds

The press is available in both floor and pit version.

The press is equipped with user-friendly graphics control panel, monitored through Siemens PLC commanded by Touch Panel installed in a pulpit station.

Platen dimensions are 3.500×3.000 mm (98×78 inches).

| Model | MIL 3530 |

|---|---|

| Max. clamping force | 3000 kN |

| Max. opening force | 1000 kN |

| Max. load capacity on lower plate | 70.000 kg |

| Max. load capacity on upper plate | 35.000 kg |

Optionally the max. clamping force can be increased to 4.000 kN.

The press can be equipped with all optional accessories except the energy accumulator and the wax injection unit.

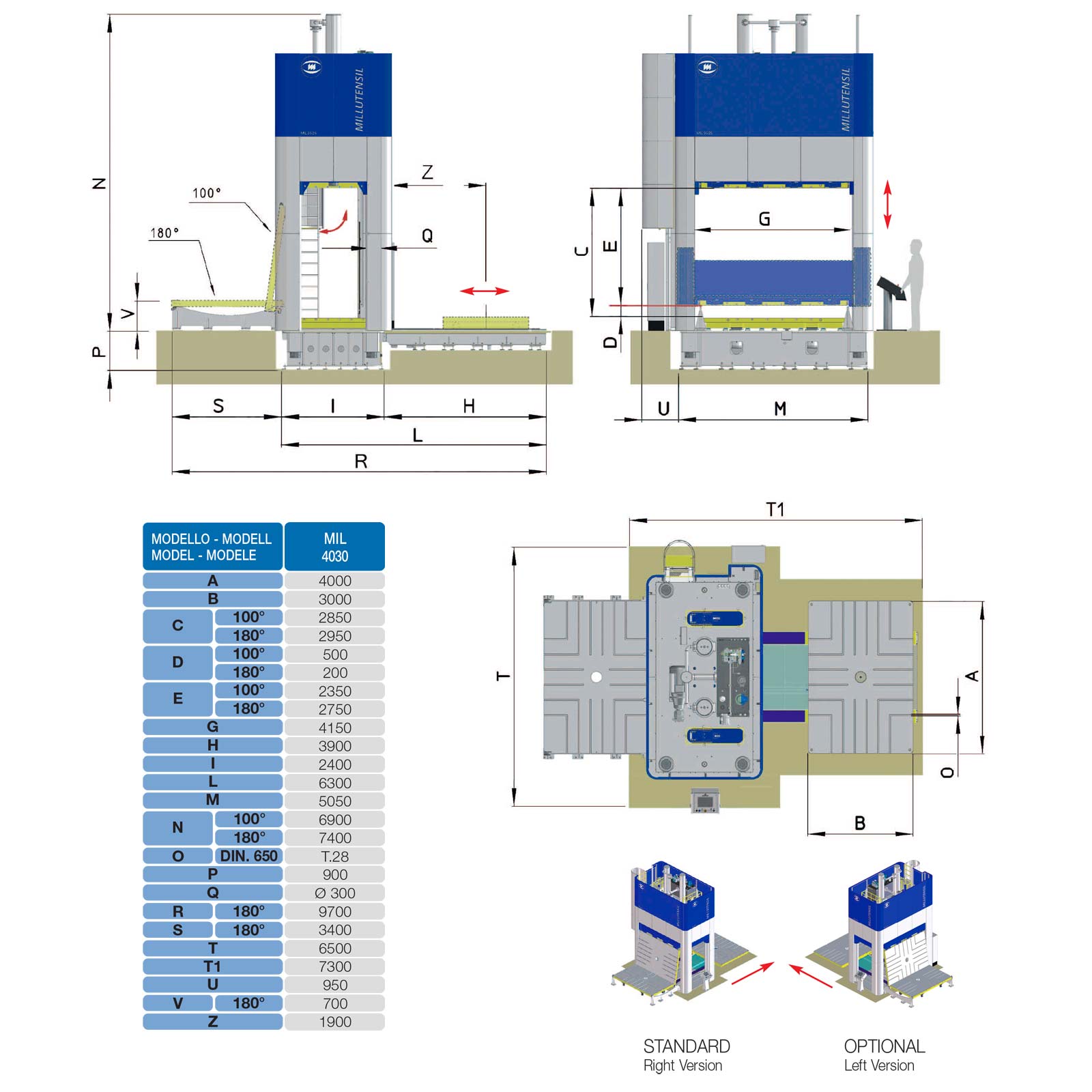

The MIL Compact series version for large size moulds

The press is available in both floor and pit version.

The press is equipped with user-friendly graphics control panel, monitored through Siemens PLC commanded by Touch Panel installed in a pulpit station.

Platen dimensions are 4.000×3.000 mm (157×118 inches).

| Model | MIL 4030 |

|---|---|

| Max. clamping force | 3000 kN |

| Max. opening force | 1000 kN |

| Max. load capacity on lower plate | 80.000 kg |

| Max. load capacity on upper plate | 35.000 kg |

Optionally the max. clamping force can be increased to 4.000 kN.

The press can be equipped with all optional accessories except the energy accumulator and the wax injection unit.

Standard equipment

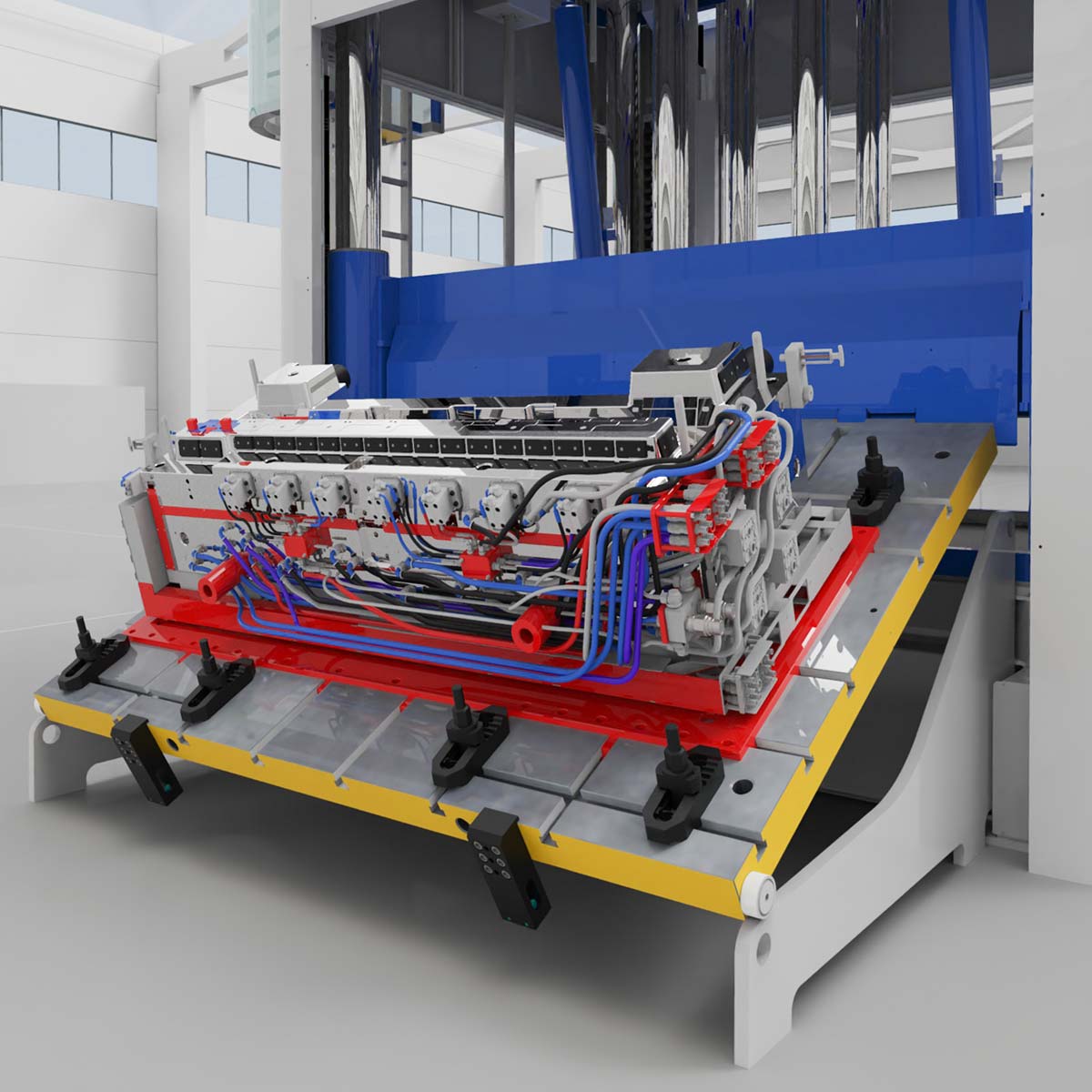

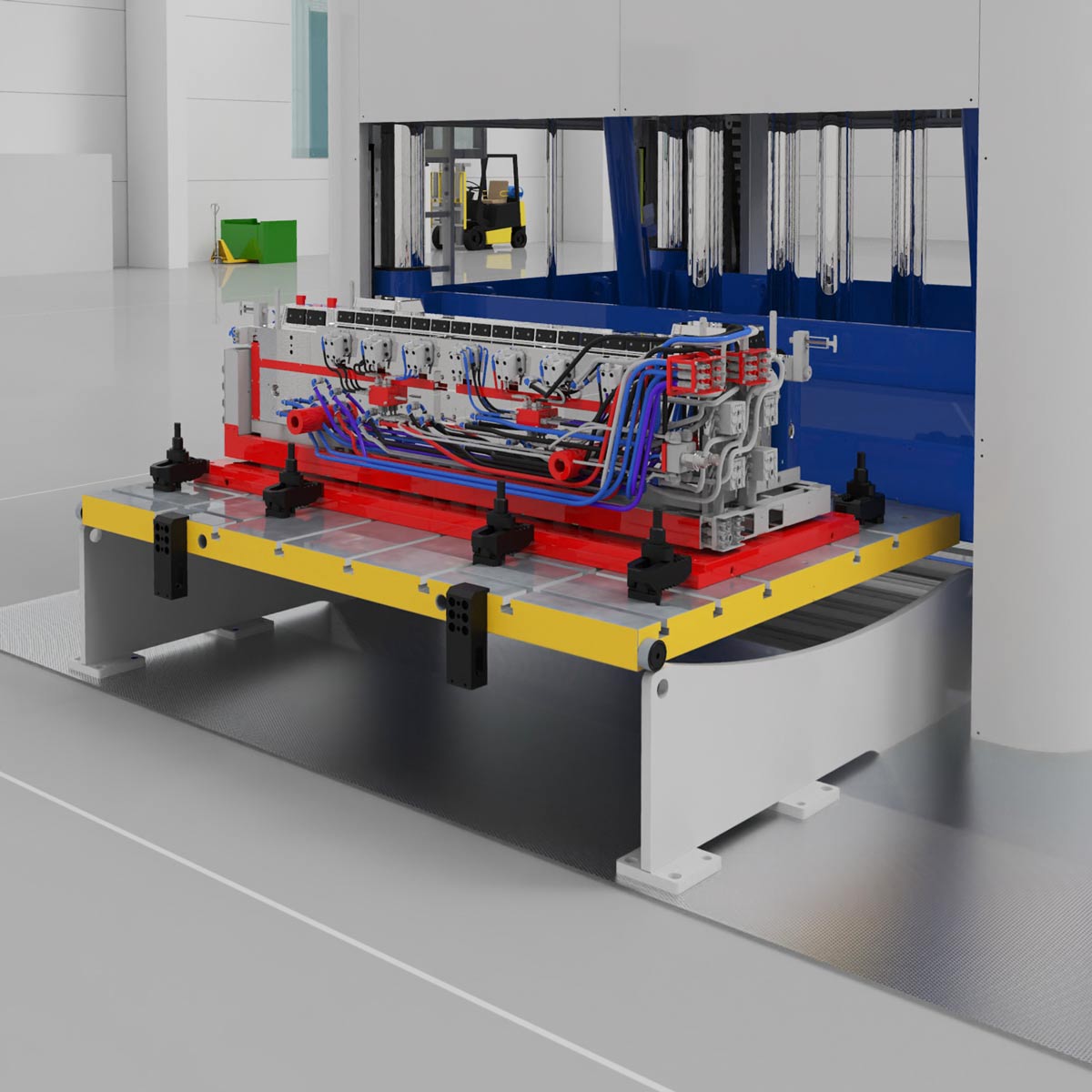

Extensible lower plate

The lower plate is extensible, driven by hydraulic cylinder.

It slides on roller bearings and is laterally guided by ball bearings, without any friction and consequent wear.

In the final position, the plate comes down and is held by means of 8 hydraulic cylinders, thus completely leaning on specific ground support bands.

The system guarantees high repeatability accuracy equal to ± 0,04 mm.

Tilting upper plate forward by 100°

For optimal access to the mould, the press upper plate can be tilted forward by 100°. By tilting the press plate on the short side, the operator can work at an optimal height, normally standing, without having to use unstable ladders, platforms or lifting equipment, which are often necessary in case of presses with long side rotation.

Moreover, with tilting rotation on the short side, the overall press height is considerably reduced. The plate features a series of T slots for the mould fastening and a central hole for the mould centering.

This means an advantageous working position, and at the same time the utmost safety at work.

Hydromechanical safety devices against the accidental fall of the upper plate

2 hydromechanical fall prevention devices on the right and left sides of the press upper plate operating for the entire stroke length.

The patented device (SITEMA) guarantees an immediate motionless locking of the upper plate in case of hydraulic pressure drop.

Different from conventional multi-hole or toothed bars, this system prevents the press ram fall in case of hydraulic system failure

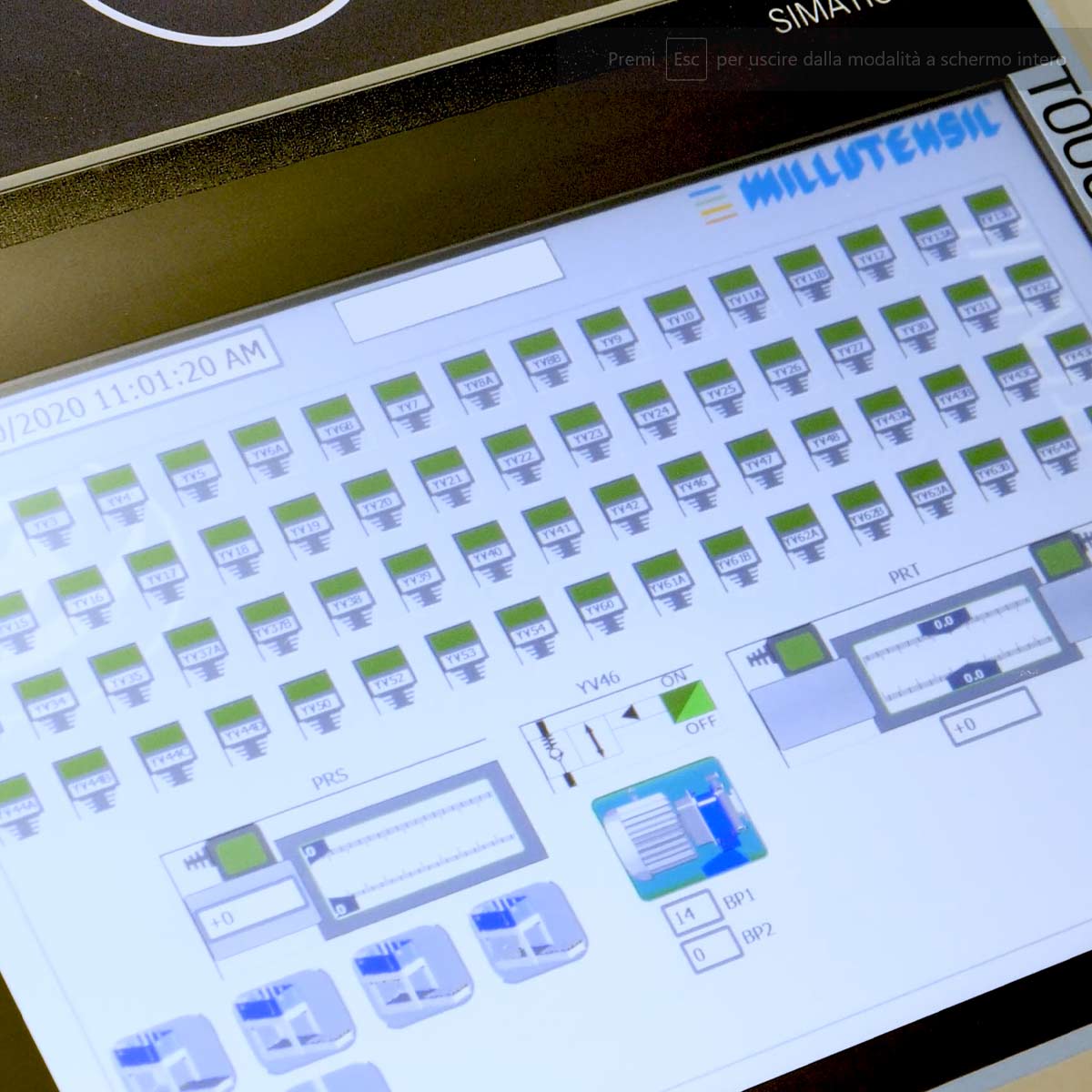

Full control of the machine

TOUCH PANEL FOR MIL SERIES – SIEMENS S7-1500 / MULTIPANEL TP1200 CONTROL PANEL

Millutensil was the first worldwide to introduce a TOUCH PANEL on its spotting presses. The electronic PLC handles all the functions of the press. Uncluttered, clear and ergonomic, the panel offers many advantages as well as vast flexibility in customizing features, including command of the auxiliary cylinders.

The control panel is equipped with a touch panel with a user-friendly graphics to simplify the use of the spotting press.

Due to security reasons, some functions can only be activated through traditional buttons (i.e. the downstroke has to be performed with two-hands in accordance to the EU safety legislation).

In the pulpit station a new Siemens multi-touch ITP 1000 can be embedded (OPTIONAL). This new Siemens multi-touch ITP 1000 is supported by a dedicated app called MyMILL© App, that has been developed by Millutensil as a result of the ongoing cooperation between Millutensil and their customers.

Integrated diagnostic system

The Millutensil -E Series die & mould spotting presses are equipped with a specific and exclusive diagnostic program. Any failures occurred during operations is displayed on the control display, where the affected point is indicated, as a result the machine downtime is minimized.

Main advantages:

- Quick and easy troubleshooting

- Considerable reduction of service costs

E-Series spotting presses are equipped with a E-Won modem, so that our Millutensil technicians can remotely operate on the spotting press to fix it.

Remote assistance service

The remote assistance can be easily performed through a mobile phone hotspot and a password that is provided in case of need.

Thanks to the Siemens multitouch ITP 1000 tablet (optional) and its MyMILL© App (optional) remote assistance is further simplified, as the tablet can be used to directly start the remote assistance call.

Standard machine colors

Standard machine colors are:

- Static parts RAL 7035 (light grey).

- Moving parts RAL 5017 (brilliant blue).

Options

Press upper plate tilting by 150°, floor version

For the versions installed on the floor only.

In order to increase comfort and improve access to the press upper plate and to the moulds fastened on it, the upper plate can be tilted by up to ~150° downwards.

This occurs through the down stroke function with the plate leaning on 2 shaped brackets. During the first phase, the press upper plate is tilted by up to 100°. After that, with the down stroke movement, the press plate leans and slides on the 2 shaped brackets up to the final ~150° position. It is possible to stop in all intermediate positions.

After complete closure, the press plate is automatically centered with high precision and locked by a system driven by hydraulic cylinders.

The use of plate tilting by up to ~150° guarantees optimal access and high working comfort in any working position.

Press upper plate tilting by 180° to the floor, pit version

In order to increase comfort and improve access to the press upper plate and to the moulds fastened on it, the upper plate can be tilted by up to ~180° downwards. This occurs through the down stroke function with the plate leaning on 2 shaped brackets.

During the first phase, the press upper plate is tilted by up to 100°. After that, with the down stroke movement, the press plate leans and slides on the 2 shaped brackets up to the final ~180° position. It is possible to stop in all intermediate positions.

After complete closure, the press plate is automatically centered with high precision and locked by a system driven by hydraulic cylinders.

The use of plate tilting by up to ~180° guarantees optimal access and high working comfort in any working position.

Lower Plate tilting by ±70°, Front/Back Side, floor version

For the versions installed on the floor only.

Thanks to 2 hydraulic cylinders, the lower plate can be tilted up to 70°, on the front and back side, to take the mould to an ergonomically better position.

Tilting movements (and automatic locking) are controlled by means of the touch panel.

The advantage for the operator is the optimal access to the mould, with no need to bend, maximum comfort and safety.

The option includes a bellow protection device and two roll carpet protection devices for the protection of the entire lower mechanical/hydraulic part, along with operator intrusion protection.

Extensible plate with integrated 0-180° or 0-90°-120°-180-240°-270° rotating table formulti-component moulds

For the fitting of multi-component or multicolour moulds, the rotating table is fully integrated in the press lower plate.

Control is comfortably performed from the touch panel. Press plate rotation is possible either in the positions 0 ° -180 ° or in the positions 0 ° 90 ° -120 ° -180 ° -240 ° -270 °. After rotation into the two final positions, the rotating table is positioned and locked by means of a hydraulic cylinder.

The rotation movement occurs by means of a large bearing/articulate coupling, driven by an hydraulic motor.

Using the rotating table, it is possible to reduce the Min. and Max. opening between plates. With this option, the Min. and Max. opening between plates is automatically considered and adjusted to the original one.

The lower plate tilting by ±70° on the front / back side (option) is only possible when the rotating table is either in the 0° or in the 180° position.

The use of the integrated rotating table guarantees greater accuracy and completely avoids the manual rotation of the mould for its spotting, which takes quite some time.

Electronic upper plate parallelism anti-unbalance safety device, protection of press and moulds

The control system is made of 4 linear magnetic encoders with decimal precision located on the external corners of the upper plate, near the columns.

They consist of an aluminium profile with an IO-Link language and a magnet for reading the position that runs close to the profile without touching it.

This device is used to continuously check the position and the parallelism of the upper plate of the press compared to the lower plate.

The values measured are dynamically displayed on the touch panel for the entire stroke.

If the pre-set limit parameters are exceeded, the ram closing movement is immediately disabled and the error is shown on the display. Parameters can be exceeded for example because the slides or hydraulic cylinders are not retracted, or tools were left in the mould (scrapers, grinders, slip gauges, hammers, etc.).

Using this system both the press and the moulds are protected from possible damage.

ENERGY ACCUMULATOR (SINGLE SHOT) – Available on MIL 122/123, MIL 142/143, MIL 162/163, MIL 202/203, MIL 252/253

This operation sets up dies and moulds for plastic materials, rubber and die casting.

It is a hydraulic device that should be fixed to the press’s upper plate. It functions to strike a shot on the closed mould, in order to better gauge the adjustment between the two mould halves (matrix and punch).

The dynamic action of this device is independent from the press clamping movement. As a result, the dynamic action of the energy accumulator will be coupled with the press clamping force.

Automatic special wax injection unit – Available on MIL 122/123, MIL 142/143, MIL 162/163, MIL 202/203, MIL 252/253

This attachment provides a way to inject special wax at a low pressure into the mould cavity.

This enables the mould maker to check dimensions and thickness of pre-production mouldings (even the thinnest flash) and to ensure the correct filling. The wax injection attachment includes: wax container with electric heating, pneumatic action with air pressure control, and temperature control of the chamber to attain constant wax fluidity.

Monitoring and collecting data

SIEMENS / INDUSTRY 4.0 WIRELESS MOBILE PANEL

Thanks to SIEMENS industrial TABLET equipped with a dedicated and copyrighted app MYMILL® specially developed by MILLUTENSIL, it is possible to monitor and collect important data for tracking costs and for improving quality.

The ITP1000 tablet is a wireless device interfaced directly with the press, conceived to perform several additional functions compared to the main control panel.

Said functions allow to easily create reports on the adjustment and maintenance of dies and moulds using the data stored by the press (e.g. mould code, operator’s name, working hours, adjustment parameters etc.). These reports can also include pictures and videos that can be easily done thanks to an integrated camera, and be easily retrieved at any time.

Separate hydraulic power unit on trolley with connections for hydraulic cylinders (4+4)

To test of slides’ and hydraulic cylinders’ movements a separate and standalone hydraulic power unit on trolley has been designed. This trolley is equipped with a tank, and it is directly connected to the press control panel, with which it is possible to settle up to 4 pairs of hydraulic cylinders (4 inputs and 4 outputs), either individually or synchronously. Each connection pair is equipped with a standalone pressure regulator and an analogue pressure gauge.

The trolley can be provided in a completely stand-alone version with its own dedicated control panel so that it can be used not only with the spotting press.

Version with extensible plate exit to the left:

We can supply a press version with extensible plate exit to the left.

In some particular situations, this version facilitates the press installation in certain working area positions. It’s possile to reach the mould loading and unloading area under particular conditions given by the transit of the overhead traveling crane.

Request MIL Series Spotting Presses Catalogue or Quotation

Simply complete the form below and we'll send you our latest catalogue. In addition you can request a quotation specifying the model of your interest.

Let's focus on Blue Line Product Categories

Spotting presses for assembly, adjustment, checking and repair of small dies

Spotting presses for assembly, adjustment, checking and repair of medium and large dies

Die splitters for assembly, adjustment, checking and repair of dies for cutting, die casting, etc.

For the safe handling / rotation heavy injection moulds, tools

and other objects