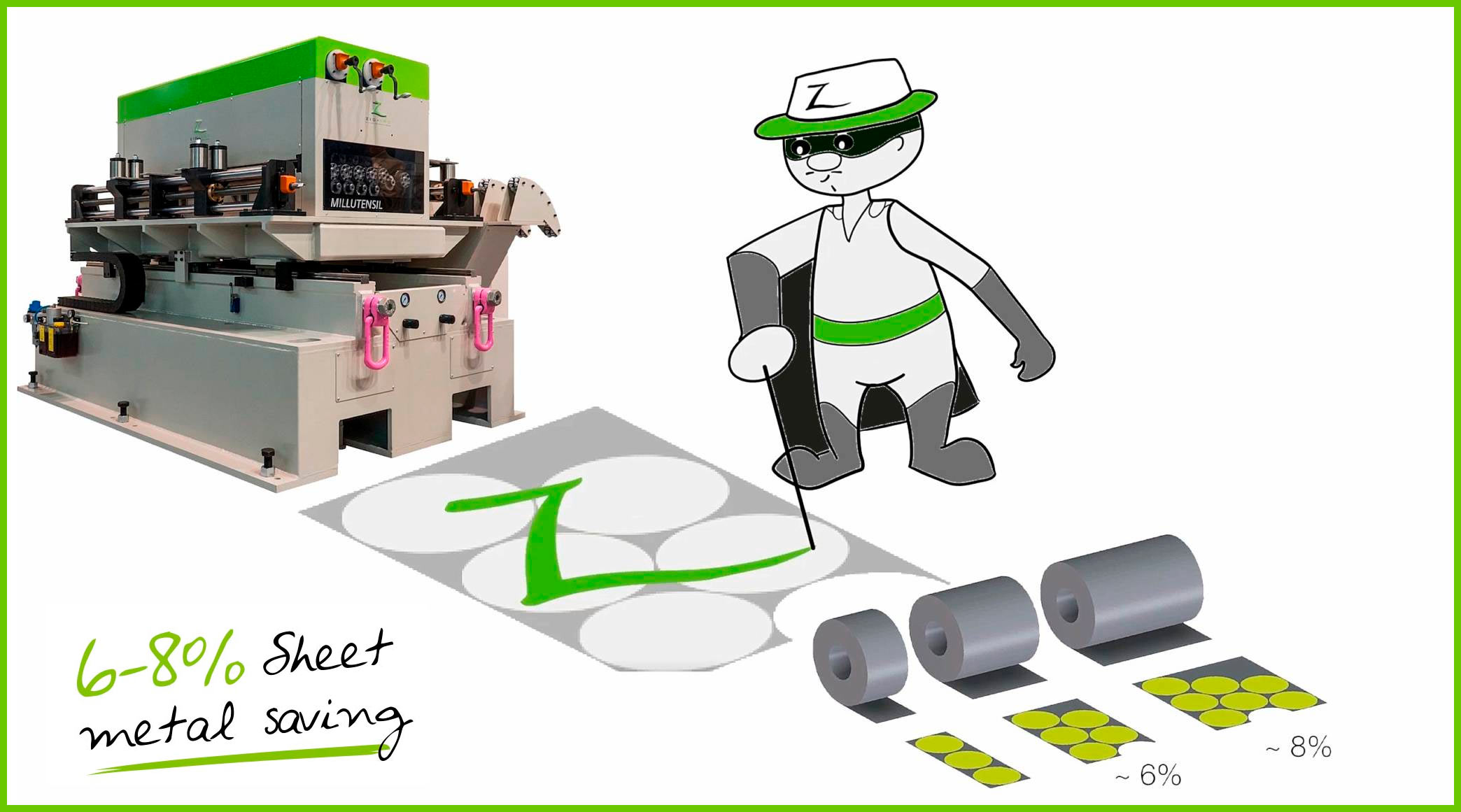

DISCOVER HOW YOU CAN SAVE FROM 6 TO 8 % OF MATERIAL

ZIG ZAG AND AUTOMATIC LINES FOR DISK CUTTING FROM COILS

Millutensil has developed the “Z” Zig zag program, a range of diverse solutions, with the aim of saving material during production.

“Z” PROGRAM GOAL

The objective of the “Z” lines is to reduce the cost of the product, which is a must for any company today.

THE ADVANTAGES

- the program guarantees a sheet metal savings of 6-8%

- considerable metal scrap reduction

- interesting payback coefficient, with a reduced investment cost

- quick and easy programming of line parameters

- optimized use of the employed material

These are ideal solutions for manufacture of:

- high-quality discs

- low-cost discs

moreover, they enable:

- an optimization of the employed material amount great savings in terms of material

- and the greatest flexibility in the production process

PROGRAMMING

The program automatically determines how to arrange discs on coil-width, optimizing the employed material and minimizing metal scrap.

Our installations

Request Green Line Catalogue

Automation for sheet metal processing

Simply complete the form below and we'll send you our latest catalogue.